Chem Process Systems Pvt. Ltd. is a premier Manufacturer and Supplier of Advanced Wastewater and Effluent Treatment Plant for Food Products, Dairies

and Breweries across India.

Our registered office is located in Sanand, Ahmedabad, Gujarat, India.

We provide efficient and cost-effective solutions designed to meet stringent environmental standards and help industries manage their waste streams responsibly.

Our treatment plants purify effluent for safe discharge or reuse, protecting the environment and supporting circular economy practices.

About Wastewater and Effluent Treatment Plant:

Wastewater and effluent treatment is vital for food, starch, dairy, brewery, and distillery industries generating organic-rich waste.

These effluents contain high organic loads, including fermentation residuals, which can cause serious environmental harm if untreated.

Our treatment plant efficiently handles complex effluents using an advanced combination of physical, chemical, and biological treatment methods.

This ensures the removal of contaminants and reduces the organic load to safe levels before disposal or reuse.

Features of Our Wastewater and Effluent Treatment Plant:

High Efficiency Organic Waste Removal: Designed to handle high COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) levels, effectively breaking down persistent organic substances.

Energy-Efficient Operation: Utilizes waste heat recovery, including vapor from drying processes or hot water from gas motor cooling, minimizing operational costs.

Compact and Modular Design: Easy installation with scalable modules to accommodate capacity increases.

Low Maintenance: Robust design ensures long-term reliable operation with minimal downtime.

Compliance with Environmental Regulations: Plants designed to meet or exceed local and international effluent discharge standards.

How Our Wastewater and Effluent Treatment Plant Works

- Pre-Treatment: Removal of large solids and suspended particles through screening and sedimentation.

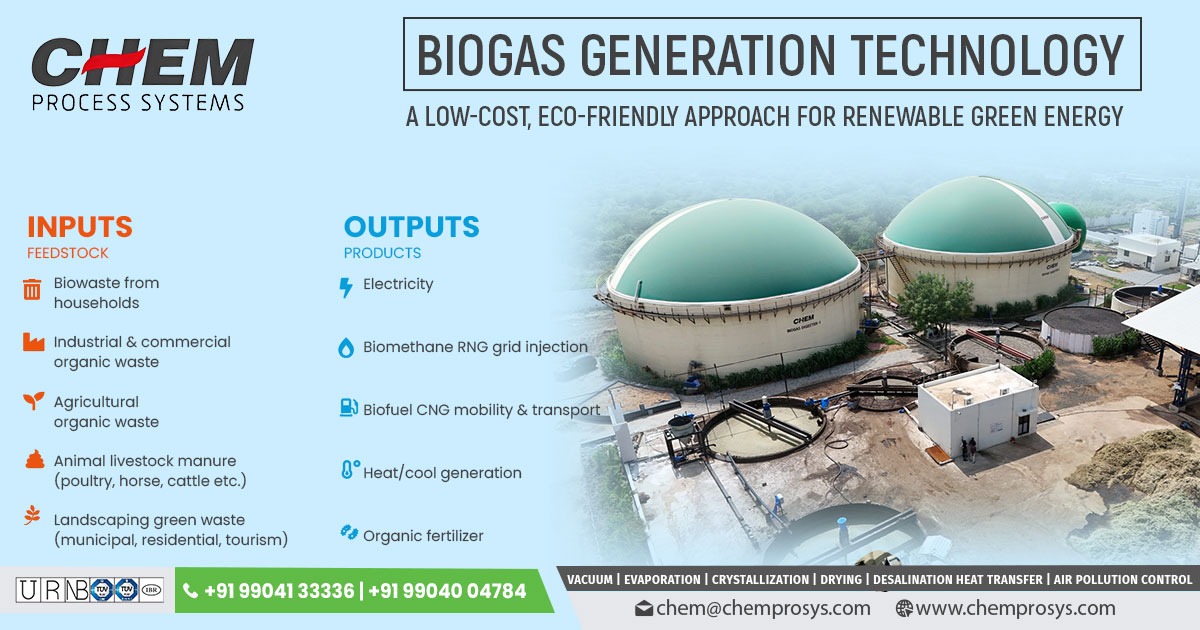

- Anaerobic Fermentation: Breakdown of organic waste substrates such as corn, grain, grass, distillery stillage, manure, and food remains in oxygen-free conditions.

- Evaporation Process: To tackle the high water content (90-95%) in fermentation residuals, evaporation significantly reduces volume, making storage and transportation cost-effective. We maximize efficiency by utilizing waste energy sources like vapor or hot water from onsite processes.

- Biological Treatment: Further degradation of organic matter by aerobic bacteria to reduce BOD and COD levels.

- Final Clarification and Disinfection: Ensuring treated effluent meets safety standards for discharge or reuse.

Uses of Our Wastewater and Effluent Treatment Plant:

Treatment of effluent from distilleries and alcohol production.

Processing wastewater from food and starch manufacturing units.

Managing high-volume organic wastewater from agricultural residues.

Reducing sludge volume through efficient evaporation methods.

Reusing treated water for irrigation or industrial purposes, promoting sustainability.

For more information of our solution for your industry, contact Chem Process Systems Pvt. Ltd. today.

View Product: Click here