Ejectors and Vacuum Systems

"Custom Designed; High Efficiency, Precise Vacuum Guaranteed"

Ejectors and Vacuum Systems

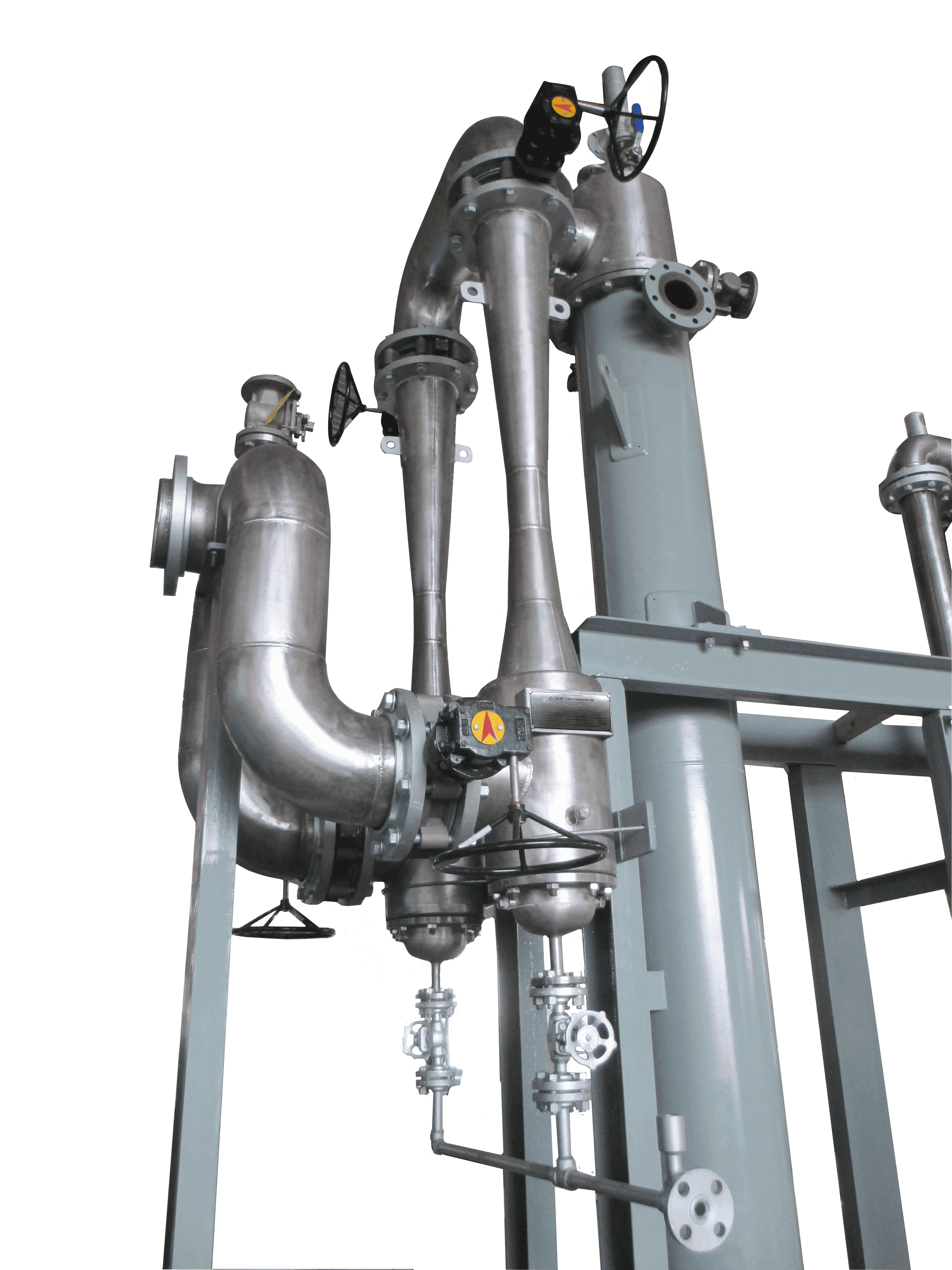

In a power plant, the primary use of vacuum systems is to remove air and other non-condensable gases from the shell side of the condenser in order to maintain design heat transfer and thus design vacuum. This, in turn, enhances the amount of energy extracted from the steam, exhausted from the steam turbine and increases the plant’s energy production. Without a vacuum system, air and other non-condensable gases would severely reduce the heat transfer in the condenser, and the plant would require a condenser with significantly more surface area for the same thermal load.Chem Process, designs and manufactures vacuum, evaporation, crystallization, drying, desalination and heat transfer equipment for the process industries and energy sectors. Having decades of experience in the design of steam jet vacuum systems, steam jet heaters, exhausters, compressors, scrubber systems, desuperheaters, thermocompressors, eductors, syphons and ejectors, Chem Process retains experienced design personnel to solve the most challenging process requirements.

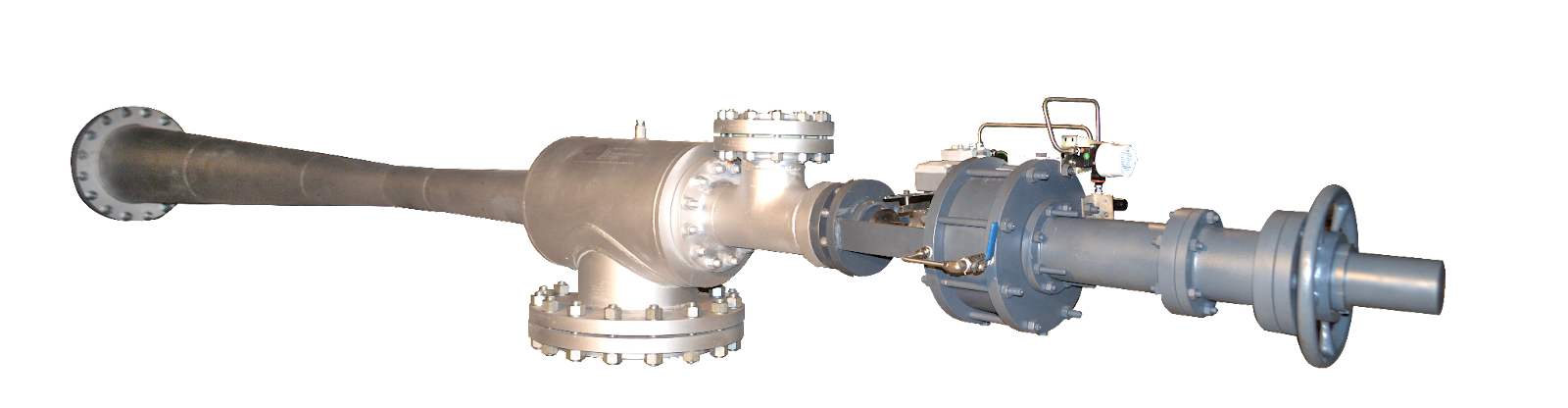

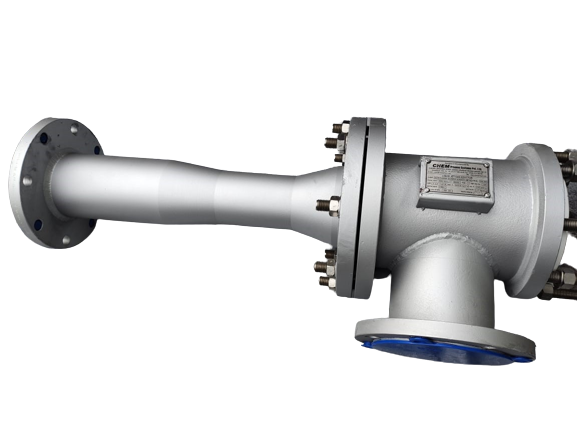

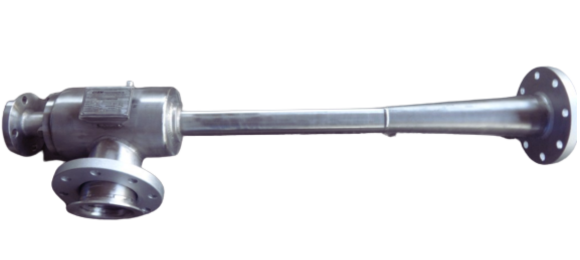

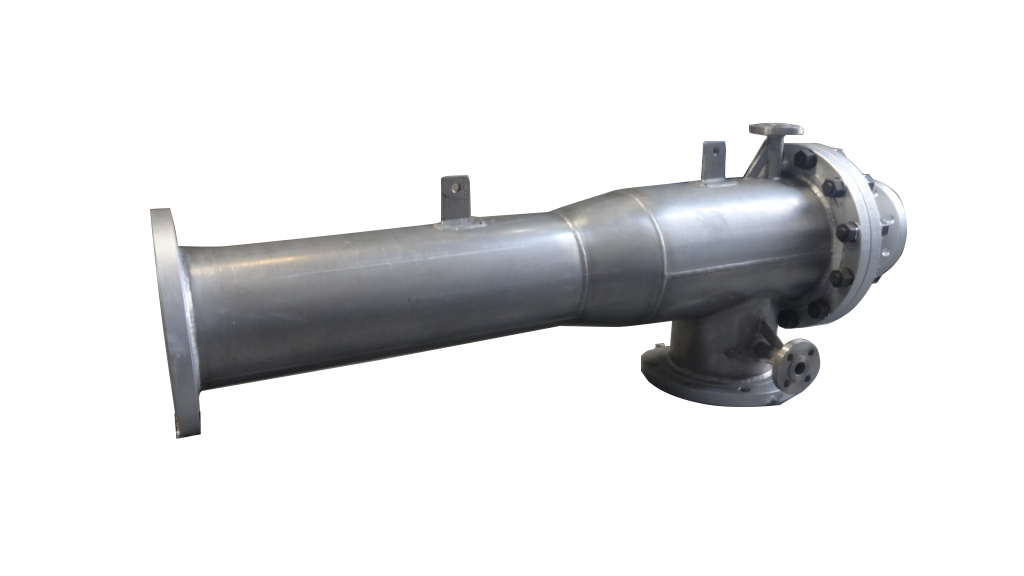

Single stage steam jet ejectors

Single stage steam jet ejectors handle both condensable and noncondensable gases and vapours and their mixtures and where small amounts of solids or liquids will not cause operating problems.

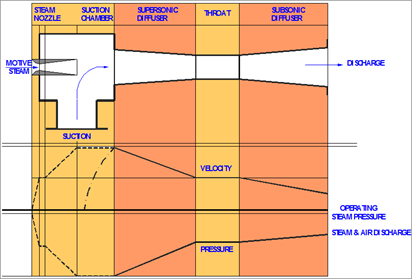

Ejector Principle

The ejectors which are distinguished from other types of compressors as having no moving parts, work on the ejector-venturi principle of Ejector Principle converting the pressure energy of a motivating fluid to velocity energy in order to entrain the suction fluid. Vacuum is created, air or gas is entrained and mixture of gas and steam enters the venturi diffuser where its velocity energy is converted into pressure energy, sufficient to discharge against a predetermined back pressure.

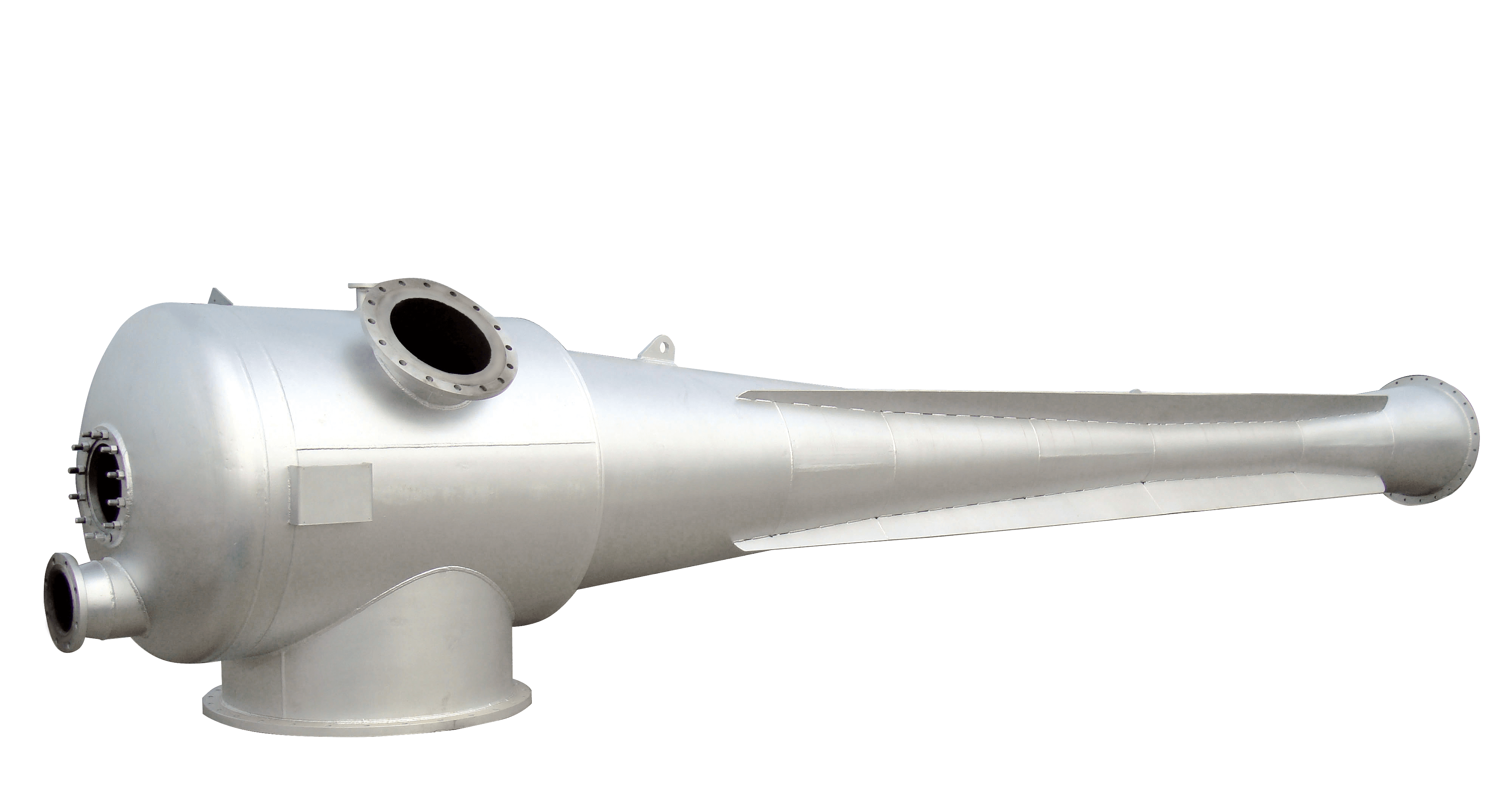

Multi Stage Steam Jet Ejector Systems

As suction pressure reduces, staging of ejectors is required to achieve economical operations. Depending on the auxiliary equipment used, two and three stage ejectors can be either condensing or noncondensing types. Four, five and six stage units are usually condensing types, but can also be non-condensing.

The usual method adopted for staging is to use a vapour condenser between the stages. The size and type of condenser used is a function of the air-vapour ratios, cooling water temperatures and utility costs.

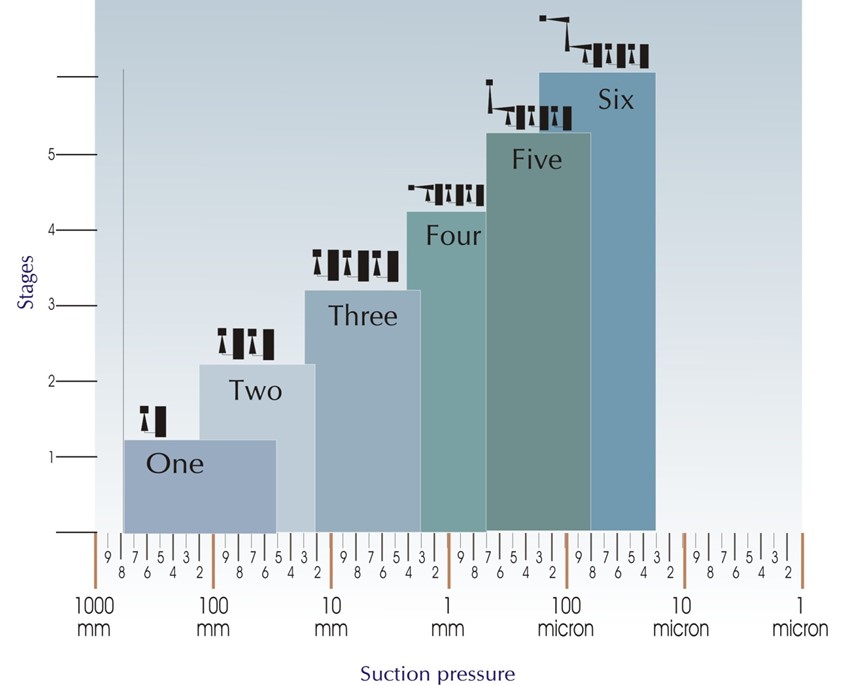

Staging of Ejectors

The graph shows the relative suction pressure capabilities of Chem Process steam-jet ejectors from single-stage through six stages. In some cases units overlap, when this occurs, a detailed analysis of initial costs and steam consumption should be made before making a decision as to the type required to meet specific requirements. Chem Process engineers should be consulted for their recommendations, which are based on their expertise and extensive experience of various

Categories Of Ejectors With Different Configurations Based On Applications

Eductors

- GAS-GAS

- GAS-LIQUID

- LIQUID-LIQUID

- STEAM-LIQUID

- SOLID-LIQUID EDUCTOR WITH CLOSED LOOP SYSTEM

Air Jet Ejectors System

- ONLY AIR JET EJECTORS

- AIR JET EJECTORS FOLLOWED BY LIQUID RING VACUUM PUMPS

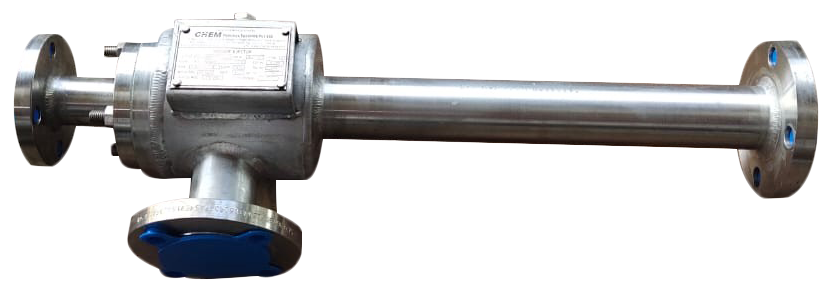

Liquid Jet Ejectors

Liquid Jet Ejectors are specially designed to operate using water, solvent or any other clear liquid and generate vacuum corresponding to the vapor pressure of the liquid. They are very useful for applications when expensive process fluid is to be recovered. They are most suitable for low non-condensable and high condensable loads in applications like distillation and evaporation. External heat exchanger can be provided to maintain liquid temperature in accordance with vacuum requirement. For higher vacuum, liquid jet ejector can be utilized along with a steam jet ejector combination system. The whole system can be supplied as a pre-assembled skid mounted unit for quick installation.

They are available in stainless steel, carbon steel, duplex steel, hastelloy, titanium, rubber lined, PP, PTFE and PVDF.

Liquid Jet Ejectors Vacuum System With Closed Loop System

How it works :

Liquid jet ejectors are jet pumps, motivated by a high pressure liquid. They use the kinetic energy of the pressure liquid to entrain gases and vapors, slurries and other liquids or granular solids and then discharge the resultant mixture against a counter pressure.

Key Advantages

- Maintenance free

- Easy to operate

- Facilitate for low level installation

- Simple in design

- Reliable in operation

- No moving parts, hence minimal maintenance

- Inline mixing of liquid and gas

- Virtually silent operation

- Suitable for hazardous areas

- Custom designed

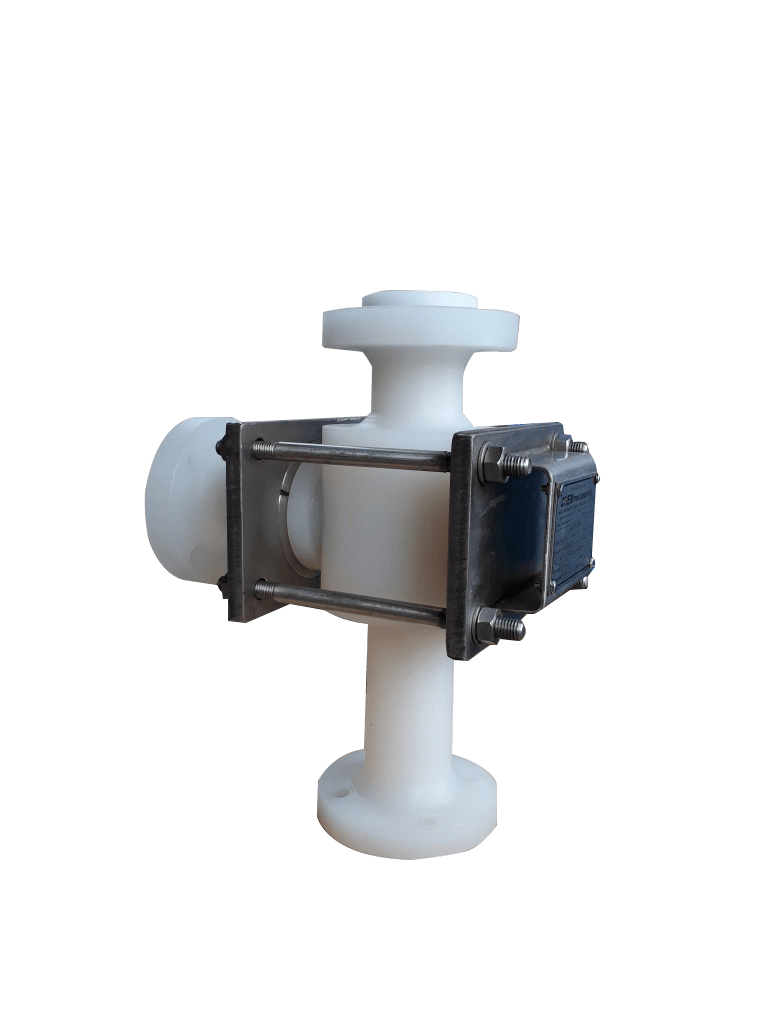

Liquid Jet Ejectors [METALLIC AND GRAPHITE MATERIAL OF CONSTRUCTIONS]

- METALLIC MATERIAL OF CONSTRUCTION WITH SHELL AND TUBE COOLER

- METALLIC MATERIAL OF CONSTRUCTION WITH THE COOLER

- NON-METALLIC MATERIAL OF CONSTRUCTION WITH BLOCK-TYPE COOLER

- NON-METALLIC MATERIAL OF CONSTRUCTION WITH THE COOLER

- GRAPHITE MATERIAL OF CONSTRUCTION WITH BLOCK-TYPE COOLER

- GRAPHITE MATERIAL OF CONSTRUCTION WITH THE COOLER

Hybrid Vacuum Systems

Combination steam jet and liquid jet ejector systems

Steam Jet-Liquid Jet Ejector Combination Systems are ideal to handle small quantities of non- condensable gases and large quantities of condensable vapors on intermittent or batch processes. Low level mounted and energy conserving with effective scrubbing of outlet gases, offers the advantage over other systems in producing vacuum and simultaneously scrubbing entrained gases before discharging to the atmosphere, making it an ideal selection for contaminated and/or corrosive applications. They are available in multi-element form as a central vacuum source on multi-purpose process applications.

They are generally used to create vacuum upto 759 mm of Hg in medium size process vessels. The system is more suitable where low capital investment is preferred. It is usually used for batch plant applications requiring coarse vacuum and low level installations.

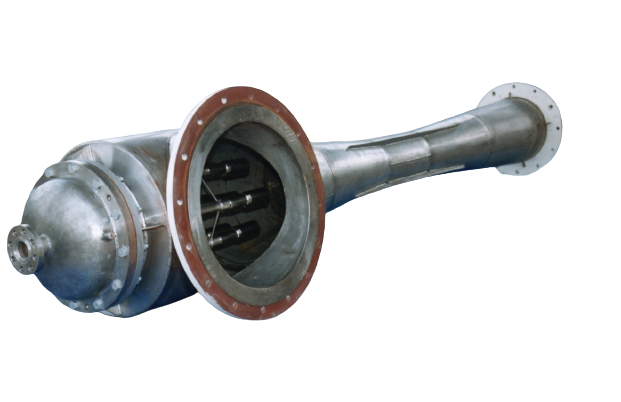

Steam jet Thermo-compressor

A Steam jet Thermo-compressor is an energy saving device that compresses low pressure steam, often waste steam, to a higher usable pressure. It offers an advantage over mechanical compressors /blowers due to its smaller size while handling a very large vapour volume under vacuum conditions. Due to its size and absence of mechanical parts, it requires a very low capital investment and a very long maintenance free service with operational safety. For a given set of operating conditions, a ratio of entrained suction vapour to motive vapour is determined and the amount of motive steam is calculated. The mass and pressure of the motive steam determines the size of the motive steam nozzle. For applications with varying operating conditions, Chem Process offers a variable nozzle design, to ensure that efficient performance is maintained over the range of desired operation. To achieve variable performance, a steam regulating spindle is fitted to the nozzle and actuated either manually or automatically.

Steam Jet Vacuum Ejectors With Direct/Indirect CondensersMETALLIC MATERIAL OF CONSTRUCTIONS

- SINGLE STAGE

- TWO-STAGE

- THREE STAGE

- FOUR STAGE

- FIVE STAGE

NOTE: FURTHER STAGING CAN BE DONE BASED ON THE VACUUM REQUIREMENT

Vaccum Condensers

Barometric Condensers

Are generally used when low cost water is available in abundant quantity. These are of simple design, and require no auxiliary air pump or pre-cooler. They are ideal when load conditions are constant and air leakage is minimal. Barometric condensers are also used when the vacuum handled is not high and a moderately large terminal difference is permissible. Barometric condensers are economical and have low capital and installation costs.

Surface Condensers

Disposal of contaminated water is of growing concern in process operations. Where an ejector system is drawing in contaminants, a condenser that discharges directly to the drain may not be used. For such applications, ejectors using surface condensers are used. The surface condenser prevents discharge to the drain and permits recovery or treatment of undesirable wastes. A steam jet ejector system with surface condensers normally requires more motive steam and condensing water than the one with direct contact condensers, and are the most expensive.

Combination Systems Steam jets + Liquid Jet Vacuum Ejectors With Closed Loop System [METALLIC MATERIAL OF CONSTRUCTION WITH THE COOLER]

- SINGLE STAGE STEAM JET + LIQUID JET

- TWO STAGE STEAM JETS + LIQUID JET

- THREE STAGE STEAM JETS + LIQUID JET

Air Extraction System

In a power plant, the primary use of vacuum systems is to remove air and other non-condensable gases from the shell side of the condenser in order to maintain design heat transfer and thus design vacuum. This, in turn, enhances the amount of energy extracted from the steam, exhausted from the steam turbine and increases the plant’s energy production. Without a vacuum system, air and other non-condensable gases would severely reduce the heat transfer in the condenser, and the plant would require a condenser with significantly more surface area for the same thermal load.

Jet Heaters

Chem Process Systems’ range of instant Jet Heaters provide a simple, low cost, silent and reliable method of heating liquid inline. Where hygienic steam boilers are applied, we have developed a range of Hygienic Steam Jet Heaters for direct contact heating of liquids for the food and pharmaceutical industries. By bringing the steam into direct contact with the cold liquid both the sensible and latent heat of the steam is fully dissipated within the liquid, making the heaters very efficient. For the food, pharmaceutical and other such industries skid mounted units use hygienic steam in direct contact with the liquid to be heated, for either process or CIP applicants.

Combination Systems Steam jets + Surface Condenser + Vacuum Pump With Closed Loop System [METALLIC MATERIAL OF CONSTRUCTION WITH SHELL AND TUBE TYPE COOLER]

- SINGLE-STAGE STEAM JET + SURFACE CONDENSER + VACUUM PUMP

- TWO-STAGE STEAM JETS + SURFACE CONDENSER + VACUUM PUMP

- THREE-STAGE STEAM JETS + + SURFACE CONDENSER + VACUUM PUMP

Eductors

Water Jet Eductors

Water Jet Eductors utilize a high pressure fluid to handle a low pressure fluid and discharge the mixture against an intermediate pressure using the Venturi Principle. Ejectors of this type are used throughout industry for pumping and mixing operations.

Steam Jet Syphons

Steam Jet Syphons are similar to the Water Jet Eductors however, they use steam as the motive force to pump, mix liquids and handle solids. In operation, steam under pressure discharges at high velocity through a nozzle and entrains the suction liquid or slurry. Both the Water Jet Eductor and the Steam Jet Syphon can be used for the handling of corrosive or abrasive liquids and solids. Their design simplicity, absence of moving parts, and because they can be made from any machineable material, make them ideal for a multitude of applications.

Solids Handling Eductors

Solids Handling Eductors employ motive air or liquid under pressure through a nozzle in the eductor that produces a high velocity jet to entrain and transport dry solids or slurries. The two types of solids handling eductors are as follows:

Steam Jet Vacuum Ejectors With Block Condensers [GRAPHITE MATERIAL OF CONSTRUCTIONS]

- SINGLE STAGE

- TWO STAGE

- THREE STAGE

- FOUR STAGE

- Pneumatic Conveying Eductors for handling dry solids: These employ motive air from a compressed air source or a blower to entrain and transport solids.

- Eductors using liquid in handling dry solids: These use liquid under pressure which issues through a nozzle in the eductor and produces a high velocity jet to transport granular solids or slurries.

Varied Flow Ejectors

Varied Flow Ejectors are specially designed Ejectors which are generally used where a low pressure steam is supposed to be enhanced to high pressure for the purpose of vacuum or suction generation. A specially designed actuating device is connected to the nozzle of the ejected whose motive nozzle needle allows a very accurate adaption of the varying pressure and volume or mass flow needs.

Applications

- Utilizing waste or low pressure steam and upgrading it to high pressure steam

- Utilizing waste steam from Low pressure for heating purpose in case of reactors, columns, evaporators or Heat exchangers

- Can be very useful in recovery of heat from hot condensate

- Advantageous in the case where a system can require different pressures (in a particular and defined range ) for different reactions or processes.

Jet Mixers

Chem Process designs and manufactures a comprehensive range of Tank Jet Mixers and complete Tank Jet Mixing Systems for the process industries. A Tank Jet Mixer is a mass momentum exchange device that uses pressurized liquid energy to entrain, mix and pump a secondary fluid. It can normally be employed on any application in which the process liquid is capable of being handled by a centrifugal pump. Factors considered in selection include tank volume, viscosity, specific gravity, size and percentage of solids as well as tank geometry. Whether the application is for mixing food products or trade effluent, Chem Process tank jet mixers offer a simple and reliable method of blending/mixing liquids and keeping solids in suspension.

Key Advantages

- Simple & Robust

- No maintenance

- No support bridges or bottom bearings

- No moving parts

- Even distribution of mixing

- Materials to suit the process liquor

- No baffles required, no vortexing

- Operate at varying levels

- Controllable performance

- Operate close to tank base

Applications

- Neutralization

- Sludge Mixing

- Flash Mixing

- Anoxic Tank Mixing

- Chemical Mixing

- Solids Suspension

- Blendings

- Heat Transfer

- Balance Tank Mixing

- Lime Mixing

Construction

Standard materials of construction include Stainless and Carbon steel, PVCu, PP, PTFE, PVDF, rubber-lined carbon steel, hastelloy and titanium. Other materials are also available. Connections included flanged, screwed or quick release hygienic.

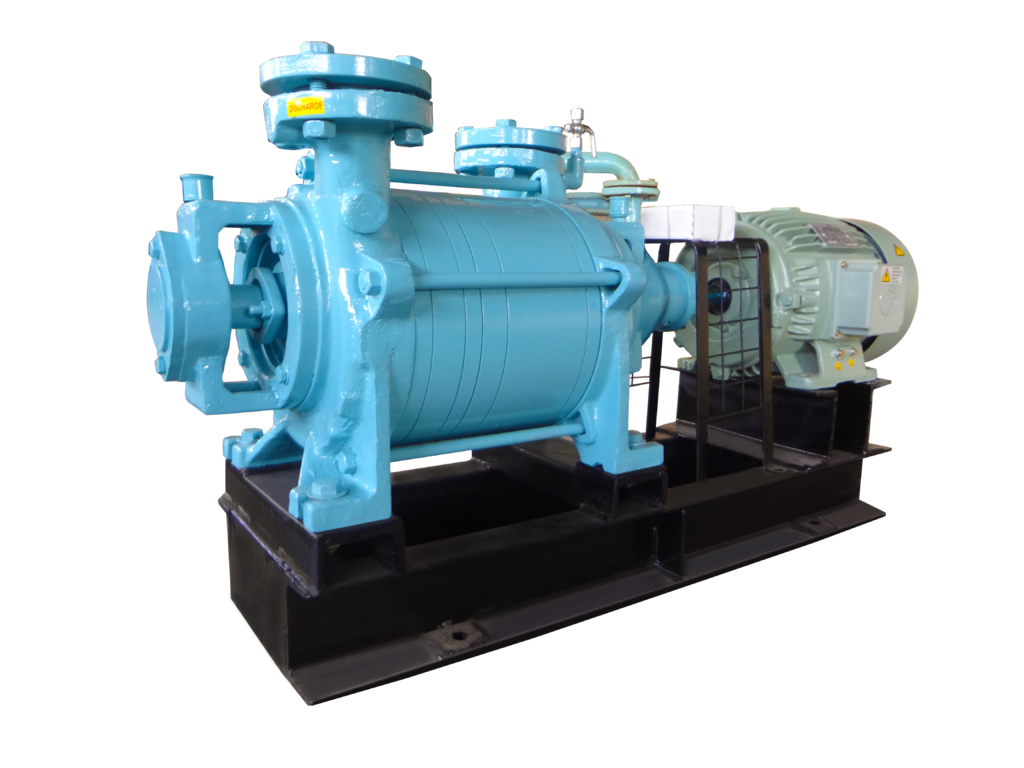

Liquid Ring Vaccum Pumps

The ejector philosophy of creating vacuum is essentially based on the fundamentals of a non moving parts system. Vacuum technologists developed a more sophisticated way of creating vacuum by means of electro-mechanical rotating equipment generalized as ‘Vacuum Pumps’. A Liquid Ring Vacuum Pump has impellers with blades attached to a center hub located in a cylindrical body but offset from the center. Ours is the optimum solution for rough and complex vacuum applications. These simple to operate pumps are perfect for processes that require vacuum upto 720 mmHg. Designed for long-term operation, these pumps are ideal for pharmaceutical, fertilizer, paper, textile, and printing industries.

How It Works

The pump requires a liquid (also called the sealant) to create vacuum. Prior to starting the pump, it should be partially filled with the liquid sealant (typically to the center of the body, although this can be plus or minus a couple of inches). The liquid can be water (making it a water ring pump), oil or a solvent, depending upon the application. When the pump is at rest, some of the impeller blades are immersed in the sealant liquid. When the pump starts, the impeller slings the liquid sealant by centrifugal force, forming a ring of liquid at the outside walls of the body. Because the impeller is off-set from the body, some of the blades are fully immersed in liquid, and some are almost out of the liquid. The area of void space without liquid, is sealed off between the liquid (and hence the term “sealant”) and between the impeller blades, called an “impeller cell”.

Vacuum Pumps With Closed Loop Systems

- WITH SHELL AND TUBE COOLER

- WITH THE COOLER

As we follow one impeller cell from the top of the pump, counter-clockwise, you can see the liquid recedes from the center hub, acting as a liquid piston to create a larger cell. This is the suction of the pump, drawing in air, gases, or vapors through the “inlet port” at the sides of the impeller. After impeller cell passes the inlet port and travels toward the discharge port, the sealant liquid is forced back toward the center hub of the impeller, creating the compression step. As the impeller cell passes the discharge port, the compression is at its highest, and the gases, along with some of the liquid sealant are exhausted through the discharge port to atmosphere. Although the diagrams show a very smooth ring of liquid, in actuality, the liquid sealant is highly turbulent, which is why some of the liquid sealant is discharged with the gases.

Key Advantages

- Simple and rugged construction

- Trouble free operation

- Easily handles dust laden and aggressive gases

- Higher capacity at higher vacuum as compare to single stage vacuum pump

Applications

- Dehydration and Filtration processes

- Distillation, Evaporation and Drying

- Deodorization Evacuation

- Sterilizing

- Conveying, Venting and Sucking

Combination Systems Steam jets + Surface Condenser + Vacuum Pump With Closed Loop System [METALLIC MATERIAL OF CONSTRUCTION WITH PHE TYPE COOLER]

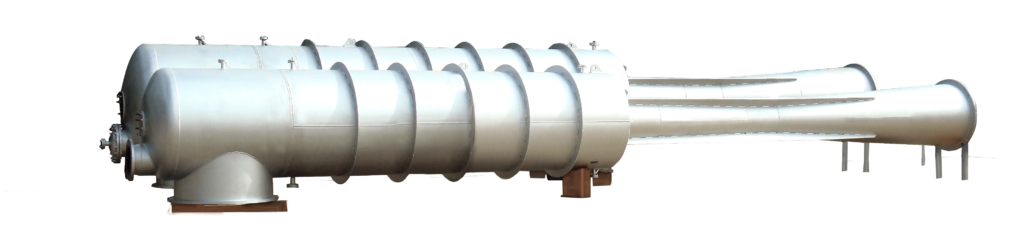

Rota Jets / Ring Jets

Ring Jets also known as Steam Jet Ejector/Liquid Ring Pump Combination Systems. They are a combination of steam jet ejector system followed by intercondenser and water/liquid ring vacuum pump. This system can achieve vacuum as high as 0.05 Torr. Our Ring Jet systems consist of single or multi-stage ejectors, single or two-stage liquid ring vacuum pumps and intercondenser. It is designed to operate at the same capacities and suction pressures as conventional ejector systems. In special cases, to avoid contamination of seal water, the closed loop for seal water cooling with indirect cooler, gas liquid separator, re-circulation tank and instrumentation is provided. The system can be installed at any elevation and is normally very compact and is easy to install.

Our Ring Jets provide a solution for high vacuum operations. They are versatile in handling both wet and dry loads; they are low level skid mounted packages fully instrumented. They offer clear energy savings and are custom designed. Highly energy efficient processing equipment are mandatory for any industry considering the ever increasing utility costs. Our Ring Jets, installed at low levels, are specially designed to take care of the energy consumption, while pulling high vacuum in various applications, in all processing industries.

We have innovated the most efficient Ring Jet Systems with the best combination of ejectors and vacuum pumps, offering the highest possible thermal efficiencies to the industries. We have also developed Ring Jets with closed loop seal water re-cycle system for vacuum pumps for the total reduction of effluent.

How It Works

The suction of the first stage ejector is connected to the process line to evacuate and entrain gases, vapors or air to maintain the consistent vacuum in the plant during the process. As per the suction pressure requirement the first stage ejector compresses the process vapor to the designed inter-stage pressure which may be selected between 8-14 mbar. The second stage ejector will take over the load from the first stage and further compress the suction gas along with the first stage steam into the surface condenser. The surface condenser is designed to condense the condensable gases and steam from the ejectors to eliminate the load onto the following stage which is the vacuum pump.

- START-UP EJECTORS AND SILENCERS

- DE-SUPERHEATERS

- STEAM JET HEATERS

- TANK JET MIXERS

The non-condensable gases/air along with the condensate produced in the surface condensers are sucked by the water ring vacuum pump. The vacuum pump is designed and selected to operate at optimum inter-stage pressure. The vacuum pump will further compress the non-condensables to the atmospheric discharge. In special cases, to obtain economy for effluent treatment the water ring vacuum pumps are provided with seal water re-circulation arrangement with cooler, gas liquid separator, re-circulation tank with instrumentation.

Our Ring Jet systems comprise of Multi-Stage Ejectors, Single & Two-Stage Liquid Ring Vacuum Pumps and Condensers, and operate at the same capacities and suction pressures as conventional Ejector Systems.

Key Advantages

- Since water is the cooling agent there is no pollution caused to the environment

- Elimination of ozone pollution

- Non-toxic

- Low level installation – barometric height not required

- Simple components: flash evaporator, condensers and ejectors guarantee uncomplicated and reliable operation

- Low maintenance costs as no moving parts

- Waste heat with a temperature down to 80°C can be used as motive energy

- Cooling capacity ranging from a few KW upto 27 MW

- Low steam and power consumption

- Skid mounted packages ready to operate at site

Applications

- Distillation

- Evacuation

- Drying

- Crystallization

- Evaporation

- Cooling

Our Ring Jets are installed at major chemical, pharmaceutical, food and various processing industries throughout India, where they provide energy efficient and consistent service for a wide variety of processing applications.

Thermo Vapor Compressors

- SINGLE NOZZLE TURBOCOMPRESSORS

- SINGLE NOZZLE TURBOCOMPRESSORS [PNEUMATIC ACTUATOR]

- MULTIPLE NOZZLES TURBOCOMPRESSORS