Waste Water and Effluent

Sharing the knowledge of Water Chemistry

Waste Water and Effluent Treatment Plants

The most common problem across all the industrial segments is the unavoidable use of water and the unavoidable contamination of water. Whether it be a small industry or a large one, each category has to deal with handling such non-value-added by-products of the industries. Till recently due to lenient legislative norms, the wastewater or the effluent could be easily sent to a flowing river or sea with partial treatment for dilution or to be precise, discarding. But due to the hazards faced by aquatic creatures across the globe, it is almost mandatory not to discard any water and further use the treated water back into the industry itself.

Chem process enjoys a unique name as the waste water treatment experts. Chem enjoys almost 30% of the total market share of MEEs to be used in Effluent or wastewater treatment. We did not stop at this particular point but we decided to go a step ahead and find out the most optimum solution so that the entire phobia of waste treatment is actually a welcome gesture by providing value-added salt and solvent recoveries from the same wastewater.

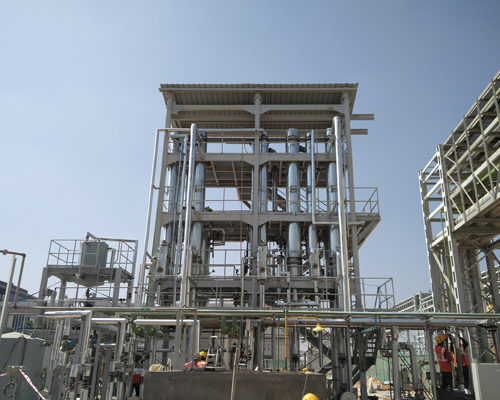

Our most advanced design coupled with the practical scenario has been the highlight of the efficient working of our Multi Effect Evaporation Plant. Whether they be Forced Circulation, Falling Film, Rising Film, Natural Circulation, or a combination of any of the above to meet the requirement. Providing Crystallizers and various dryers completes the entire Zero Liquid Discharge norms, providing Solids for reuse or landfill or incineration, while the water is sent back to the plant for process makeup, gardening, sanitation, or some other dilution.

The Subject of getting pure, potable, and consumable water has become popular in the recent decade. The reasons being simple enough that the underground brackish water or seawater though available in plenty have limited applications due to presence of salts or different contaminants.

Chem Process Systems with its innovative approach has come up with very refined and simple thermal treatment technology by using simple multistage evaporators to tee off the dissolved solids and other contents and acquire pure usable and potable water. The purity limits for the potability of this water are well under the prescribed and required norms.

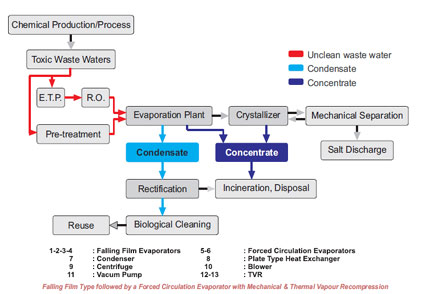

Treatment of Waste Waters from Chemical Productions/ Processes

In the production processes of various pharmaceuticals, bulk drugs, agrochemicals, pesticides, dyes, dyes intermediates, textile, power, water treatment, galvanizing and various other chemical industries; waste waters produce essentially consist of several organic components, salts and water. Treating these waste waters is very difficult as they are toxic and cannot be treated in a bio-reactor due to high salt contents and hence also hinder dumping. The only method of disposal is to remove all the water, solvents and produce solids for reuse/disposal. In case of high COD contents having high boilers, the only option of disposal is by incineration. In such cases too, concentration prior to incineration is recommended. Both these tasks of concentration and separation can be optimally achieved with thermal treatments, technologies consisting of evaporation and crystallization.

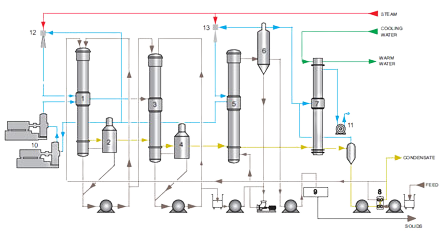

Process Description :

The water portion is concentrated in the evaporation plant. The salt is separated by crystallization which may be by way of evaporative crystallization or a separate crystallizer arranged downstream of the evaporation plant. Then if required the volatiles are removed from the vapor condensate in a rectification column/stripping. Thus only the concentrated organic matter which is very small in quantity has to be incinerated.

Treatment of Waste Waters of Food, Starch and Distilleries

Raw materials for bio-gas production are so-called fermentation substrates, such as corn, grain and grass, stillage from distilleries, manure, biological waste, remains of food and other fermenting residuals. After the anaerobic fermentation there are fermentation residuals, a mixture of persistent organic substances. The disposal of these fermentation residuals is decisive for the costefficiency of a bio-gas plant. Its storage and transport to agricultural areas is cost-intensive since the produced fermentation residuals are large (water contents 90 – 95 %).

Evaporation strongly reduces the quantity of fermentation residuals and therefore contributes to a solution of these problems to a large extent. The efficiency of evaporation will be particularly high if waste energy sources, such as vapor from a drying process or hot water from gas motor cooling can be used as heating medium.

Process Description :

The fermentation residuals are de-watered in decanter centrifuges. The phase with high portion of solid matters is supplied to the dryer. After acidification and de-gassing, the liquid phase is evaporated. The concentrate of the evaporation plant is dried together with the solid matters from the decanter. The vapor condensate is further cleaned in a membrane filtration plant or in an alkaline water scrubber, and can then be used as process water. The energy for the plant operation comes from small de-centralized block heating power stations.

Treatment of Waste Waters from Biotechnological Processes

Production / Processes :

In biotechnological production/processes, a biological treatment is not efficient, or is too complex because the continuation levels of organic substances and salts are very high. However these contents may be suitable for the production of fertilizers and animal feeds/fodder. Hence the best treatment solution for these waste waters is to first concentrate them in an evaporation plant and then dry the residual matters for further use in the production of fertilizers/animal feeds/fodder.

Biotechnological Processes :

- Drinking Alcohol Production

- Ethanol Production

- Glutamic Acid Production

- Lysine Production

- Yeast Production

Industrial produce of Wastewater or commonly termed effluent has different characteristics based upon the solid content, soluble content, and oxygen demands as per the industrial segment. Due to various norms, the water has to be treated by means of different methods separating pure water from the rest of the content. Chem process has a unique range of processes to take care of your effluent starting from

Zero Liquid Discharge Systems

Large quantities of industrial waste waters/effluents with strong contaminations of different compositions are generated in the production and processes of almost all industrial sectors. These waste waters have to be treated before they can be discharged into the specified permissible system.

Hence an efficient and environmentally friendly waste water treatment is required. Chem Process partners with you to provide the best solutions for treatment of industrial waste waters.

As one of the leading designers and manufacturers of thermal and mechanical process equipment with core competence in evaporation, crystallization, vacuum and heat transfer, Chem Process offers custom made plants with additional upstream or downstream process steps. Suitable combinations of processes in our plants achieve optimum results for the recovery of water and valuable products.

Technologies

During the design of evaporation plants, numerous factors have to be taken into consideration viz. waste water specific product values, power and utility costs and site condition. The type of construction and arrangement, other process engineering and operational data are based on these parameters.

Research & Development

Chem Process has an in-house research and development centre with the required laboratory equipment, where waste waters are tested and treated for their behavior and based on the results, appropriate plant components, pre and after treatment are selected and designed. Mobile pilot plants are also available, which if required are sent to our customer’s location for carrying out tests.

Energy savings are possible by :

- Heating with Waste Heat

- Multi-Effect Evaporation

- Thermal Vapor Compression

- Mechanical Vapor Compression

If the characteristics of the waste waters cannot be clearly defined and if its constituents, dry matter contents, pH or particle size change frequently, and if they have to be concentrated substantially, then thermal separation is the best solution.

Energy consumption determines the operating costs of evaporation plants. With our ingenious thermo-technical combinations, the plant energy requirement is minimal.

Salient Features

Plants designed and engineered by Chem Process are recognized for their high quality, efficient performance and economic operation. All process and functional requirements are taken into consideration and hence operations of a Chem Process designed plant are reliable and operator friendly.

- Operation reliability is high

- Long plant life

- Good performance even at partial capacities

- Custom designed plant configurations

- Bespoke component designs

- Combination of several process steps, which include pre and after treatment

- Maximum concentration of waste waters

- Minimal use of chemicals

- Total separation of solids

- Condensate/distillate water has salts > 100 ppm

- Minimal residual bleed and solid matter quantities, hence low disposal costs

- Good condensate quality, hence can be reused as process water in most cases

Our scope of services include consultancy, design, engineering calculations, manufacturing, quality control, delivery, supervision of erection, commissioning and after-sales services. Chem Process has:

- Delivered to more than 800 plants

- Extensive knowledge on products to be handled

- In-house research and development centre with laboratory and pilot plants

- Mobile pilot plants available for on-site trials

- A wide sales network of representatives and partner offices

- ISO 9001 2008, Asme ‘U’ and National Board ‘R’ Stamp certified fabrication shop