Chem Process Systems Pvt. Ltd. is a premier Manufacturer and Supplier of Wastewater and Effluent Treatment Plant for Biotechnological Processes across India.

Our registered office is located in Sanand, Ahmedabad, Gujarat, India.

In the realm of biotechnological production, wastewater management poses unique challenges due to the high concentrations of organic compounds, salts, and other complex components.

Traditional biological treatment methods often prove inefficient or overly complicated in such scenarios.

Chem Process Systems Pvt. Ltd. offers an advanced solution tailored specifically to handle these complexities—our Wastewater and Effluent Treatment Plant (WWTP/ETP) for biotechnological processes.

Our state-of-the-art system is designed not only to treat and manage high-load effluents but also to maximize resource recovery.

By focusing on the evaporation and drying of concentrated effluents, we enable the conversion of waste streams into value-added products such as fertilizers and animal feed ingredients. This makes our solution both environmentally responsible and economically beneficial.

Biotechnological Processes Served

Our wastewater and effluent treatment systems are tailored for a wide range of biotechnological production processes, including:

- Drinking Alcohol Production

- Ethanol Production

- Glutamic Acid Production

- Lysine Production

- Yeast Production

These processes often generate complex, high-load effluents that demand robust treatment beyond conventional biological systems.

Features:

- Multi-effect evaporators with optional mechanical vapor recompression (MVR) for energy efficiency

- High-performance drying systems (spray dryers, rotary dryers, etc.) for converting concentrate to dry solids

- Corrosion-resistant materials and design suitable for harsh effluent composition

- Integrated automation and control systems for optimized performance

- Modular and scalable systems for flexibility in capacity expansion

- Capability to integrate Zero Liquid Discharge (ZLD) frameworks

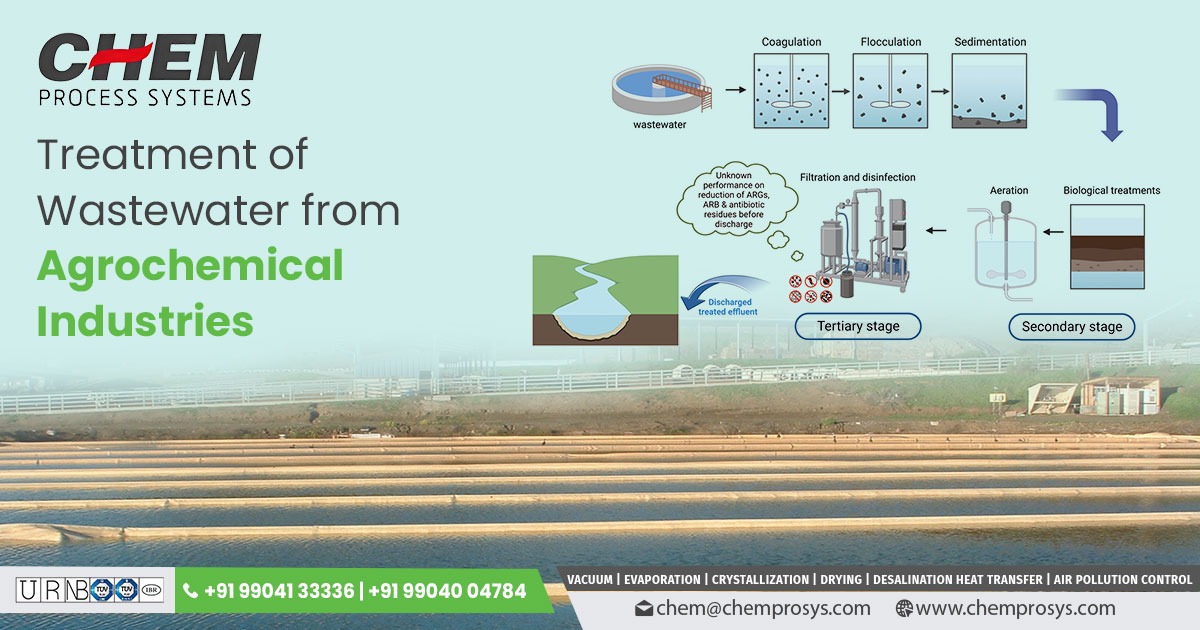

How Our Wastewater and Effluent Treatment Plant Works

- Effluent Collection & Pre-Treatment

Initial separation of coarse solids and pH adjustment to prepare the effluent for thermal treatment. - Evaporation & Concentration

A multi-effect evaporator system processes the high-organic and saline effluent to concentrate dissolved and suspended solids. - Residue Drying

Advanced drying technologies dry the concentrate from the evaporator, producing safe and useful solid output. - Solid Recovery & Reuse

We collect dried solids for further processing or direct application in fertilizer or animal feed production. - Condensate Treatment (Optional)

The plant may reuse or safely discharge cleaned condensate, ensuring water conservation and compliance.

Applications and End Uses

- Fertilizer Production: You can repurpose concentrated and dried effluents rich in nitrogen, phosphorus, and potassium as agricultural nutrients.

- Animal Feed/Fodder: Protein-rich residues from amino acid and yeast production serve as nutritious feed supplements.

- Water Reuse: Treated condensates can be reused within the plant processes, reducing freshwater dependency.

- Compliance and ZLD: Ensures companies meet environmental discharge norms and move toward Zero Liquid Discharge goals.

For more information of our solution for your industry, contact Chem Process Systems Pvt. Ltd. today.

View Product: Click here