Bio Fractionation Technology

A Low-Cost, Eco-Friendly Approach for

Renewable green Energy

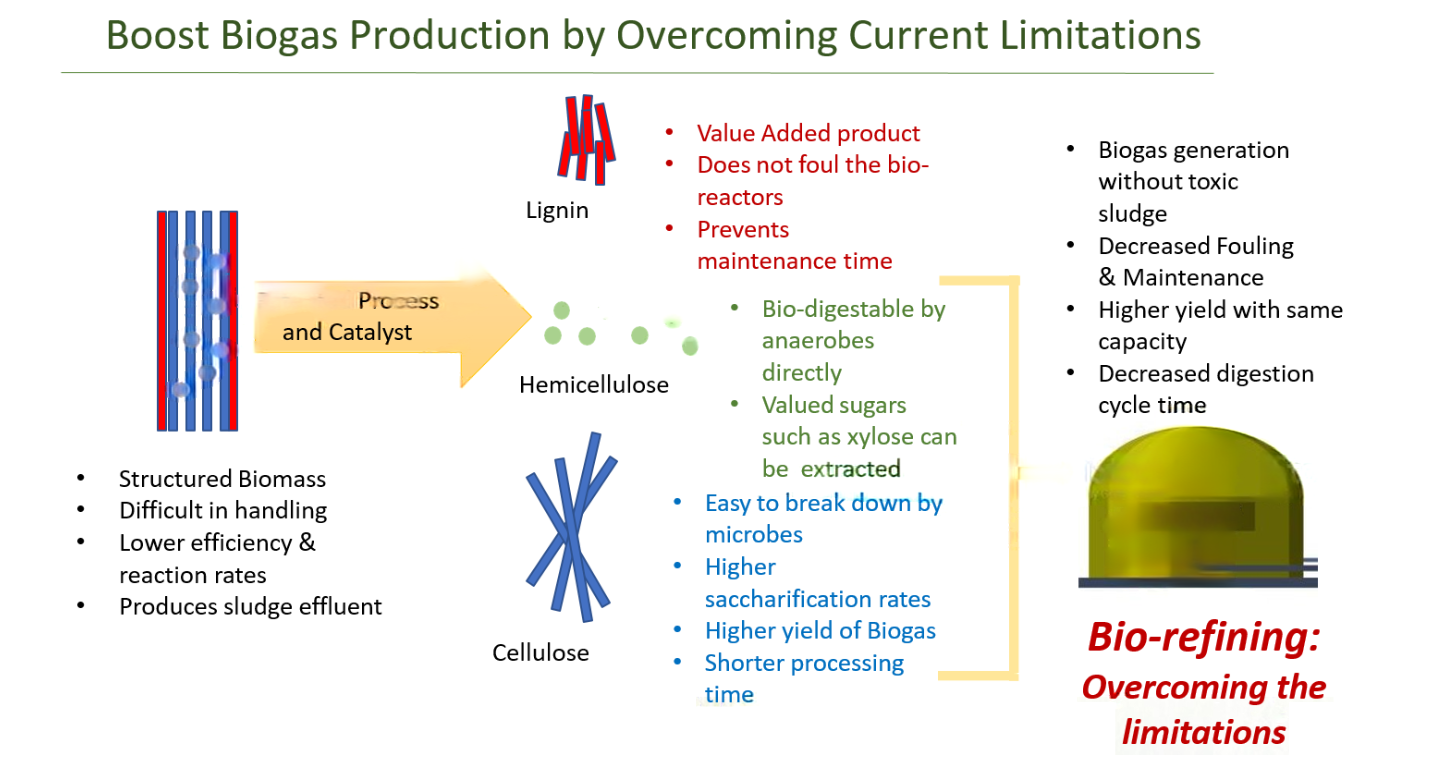

Biogas production is renewable energy source and offers promising

avenue for meeting energy demands while curtailing and reducing greenhouse gas emissions.

Transforming Agri-Waste into Green Chemicals: A Sustainable Revolution

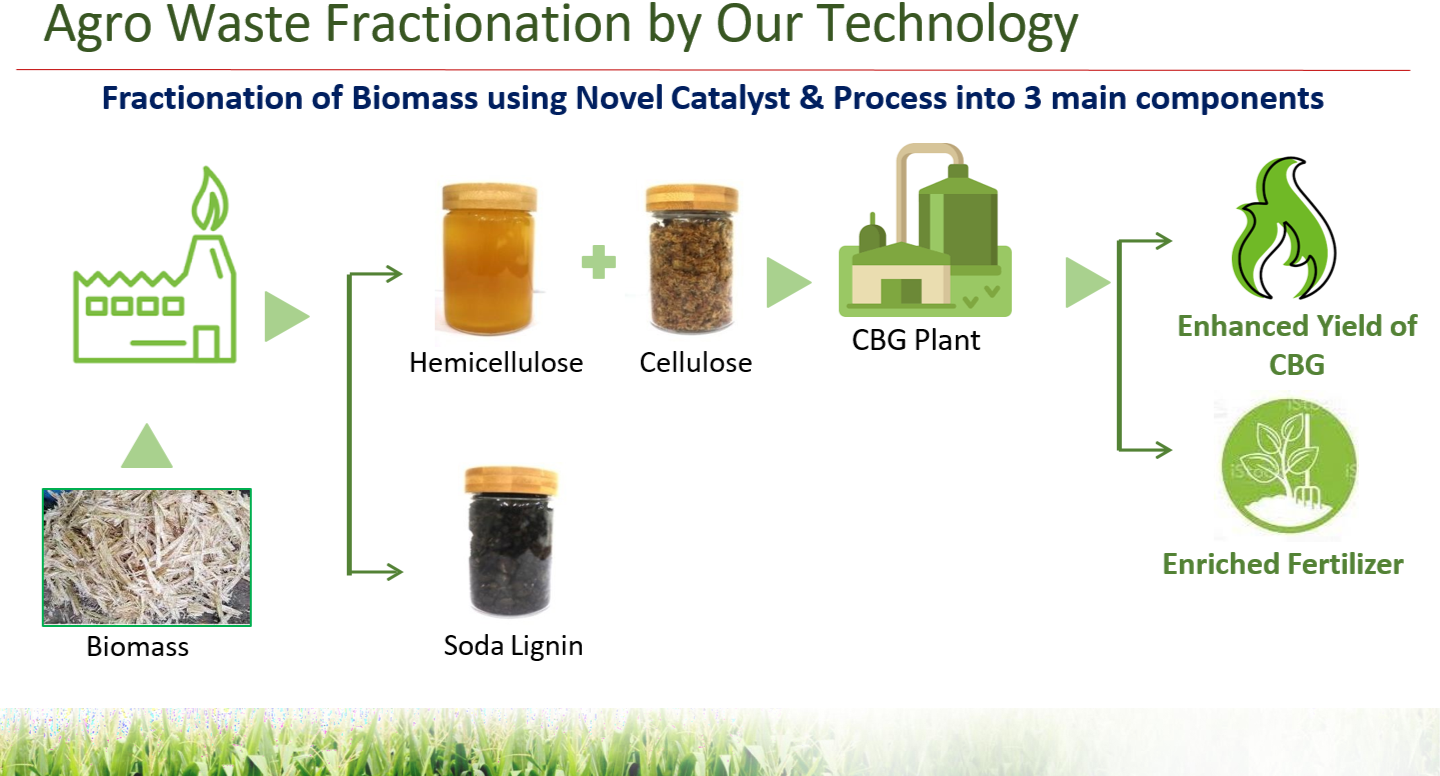

At Chem Process, we’re turning agricultural waste into the building blocks of a greener future. By leveraging advanced technology, we transform agri-waste into sustainable biochemicals, fuels, polymers, and materials—maximizing every part of the biomass for eco-friendly production.

Agri-waste is a treasure trove of organic polymers :

- Cellulose (50%) : The primary strengthening material in biomass, providing structural support.

- Lignin (25%) : Adds rigidity and resistance to water and degradation.

- Hemicellulose (25%) : Binds cellulose and lignin, aiding in water storage within cell walls.

At our Bio Fractionation Plant, we combine innovative chemistry with sustainable wood processing to extract and refine these polymers into high-value chemicals.

Revolutionizing Rubber and Plastics

Chem Process RFF is a game-changer for rubber and plastic industries:

- Reduces Carbon Footprint : Replaces CO₂-intensive materials like carbon black and precipitated silica, cutting environmental impact by 50% or more.

- Lightweight and Efficient : 25% lighter than carbon black and 35% lighter than precipitated silica, enabling up to 20% weight reduction in final products.

- High Performance : Enhances rubber’s resistance to non-polar media and supports advanced processing techniques for high-quality production.

Our Process: From Waste to Value

1. Sourcing Sustainable Biomass

– We responsibly source thinning and industrial hardwood from regional forests. The wood is debarked, chipped, and pre-treated to separate hemicellulose.

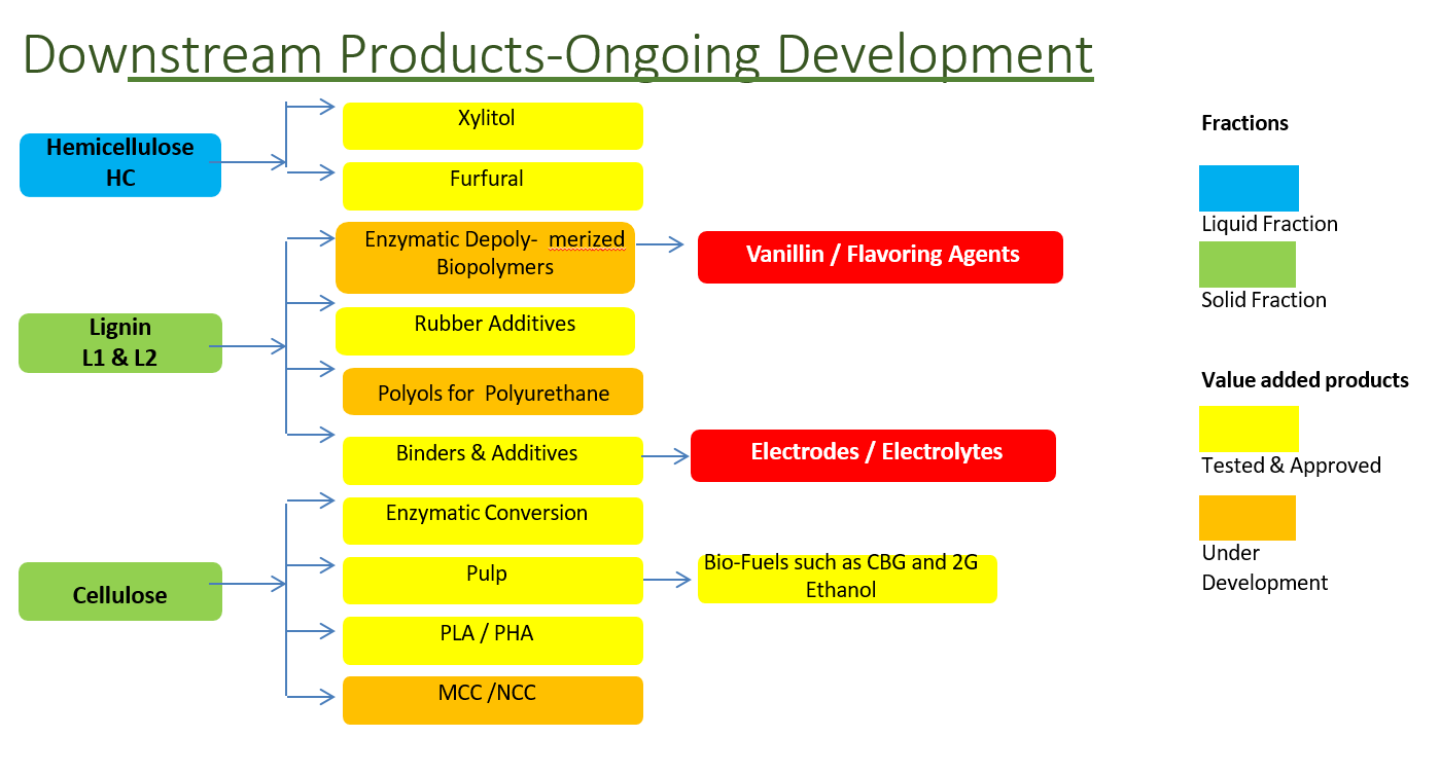

2. Hemicellulose to Industrial Sugars

– Hemicellulose is converted into industrial sugars, which are further processed into fuels, food, and polymers.

3. Cellulose to Renewable Glycols

– Through enzymatic processes, cellulose is transformed into renewable glycols like BioMEG and BioMPG. These 1:1 drop-in replacements enhance sustainability in textiles, coolants, and packaging.

4. Lignin to Advanced Biochemicals

– Lignin, often underutilized, is converted into Chem BioMotion™ RFF—a sustainable alternative to carbon black and precipitated silica in rubber and plastic applications.

Why Choose Chem Process Biochemicals?

- 100% Biobased Carbon Content : Verified through ASTM D6866 testing, our products are derived from renewable resources, capturing carbon during plant growth.

- Safe and Clean : Exceptionally low levels of PAHs (Polycyclic Aromatic Hydrocarbons) ensure compliance with stringent EU and Indian regulations, making our products safe for consumer goods.

- Biodegradable and Compostable : Certified under IS 17088, our biochemicals are biodegradable in industrial, home, soil, and marine environments, supporting a circular economy.

Applications Across Industries

- Thermoplastics : Chem Process RFF provides a distinctive black color, thermal stability, and recyclability, making it ideal for packaging, automotive components, and more.

- Biodegradable Products : Suitable for compostable applications, our biochemicals support circular economy goals.

From Concept to Market: Your Partner in Innovation

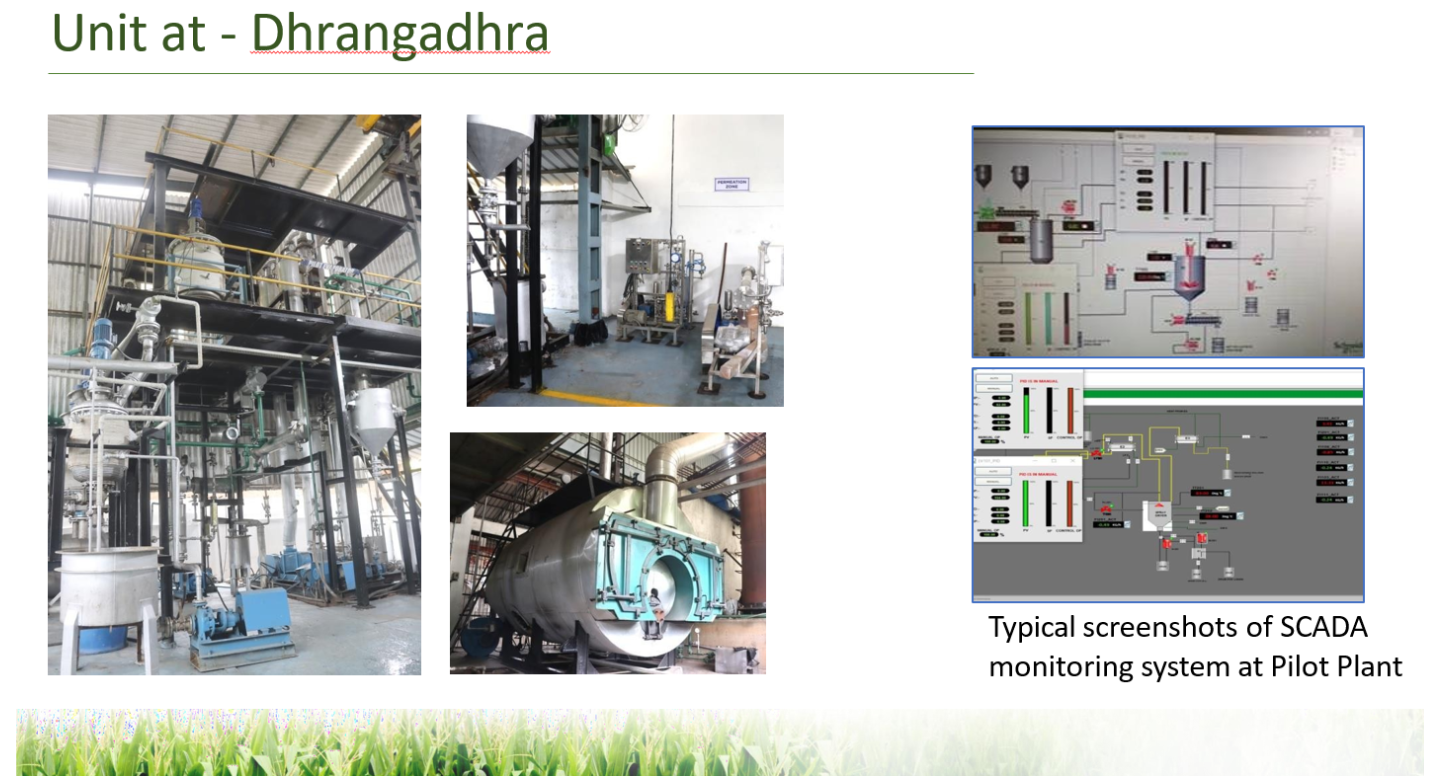

Our expert team guides you every step of the way—from selecting the right Chem Process RFF grades to optimizing performance and processing parameters. Located in Ahmedabad, our Application Development Centre offers advanced testing and processing capabilities to ensure your applications achieve optimal results.

Join the Green Revolution

“At Chem Process, we’re committed to creating biochemicals from responsibly sourced agricultural waste. Our solutions offer a significantly lower carbon footprint compared to fossil-based alternatives, driving the transition to a circular economy.”