Filters

"Particulate Engineering for Efficient Separation "

Belt Filters

The term filter itself indicates the matter of the fact that a higher particle size needs to be segregated or separated from a lower

Best In Class Belt Filters - Customized To Your Satisfaction

The term filter itself indicates the matter of the fact that a higher particle size needs to be segregated or separated from a lower particulate size, from a mix forming a solid-solid mix or a solvent and solute mix. This is generally done by incorporating a fine go through membrane, which allows passing of particles with lower particle size. This is one of the most common and effectively practiced means of separation since long time.

Belt Filters are a device which is made up of a membrane generally used in separation of solids and liquids. The system is so designed that the membrane forms a long and continuous belt structure which is passed over The belt press may be fitted with a highly efficient belt pre-dewatering unit of the same high standard design as the belt press. The belt speed may be adjusted by means of a frequencycontrolled gear motor. All monitoring functions may be integrated in the control cabinet of the belt press. The pre-dewatering unit is typicallyfitted where the dry matter content of the sludge is below 2%. If you would

various drums or rollers, and these drums are kept under rotation, which initially allows the liquid to pass by gravity and since the rollers are rotating it builds in a squeezing process allowing the remaining liquid to pass through the membrane belt and keeping the solids on the other side.

The Belt Filters are generally used in the Sludge dewatering, Solid recovery from slurries or in Juice or pulp extraction in Fruit and vegetable

industries. Since it is a simple mechanism, and works on low pressure fundamentals it is widely used in the applications where the quantity of

fluid is in small scale and the primary intent of the process is to just separate the maximum solid-liquid.It is a continuous process. Generally

the solids that are received at the end of the process carry 12% – 15 % moisture of the liquid.

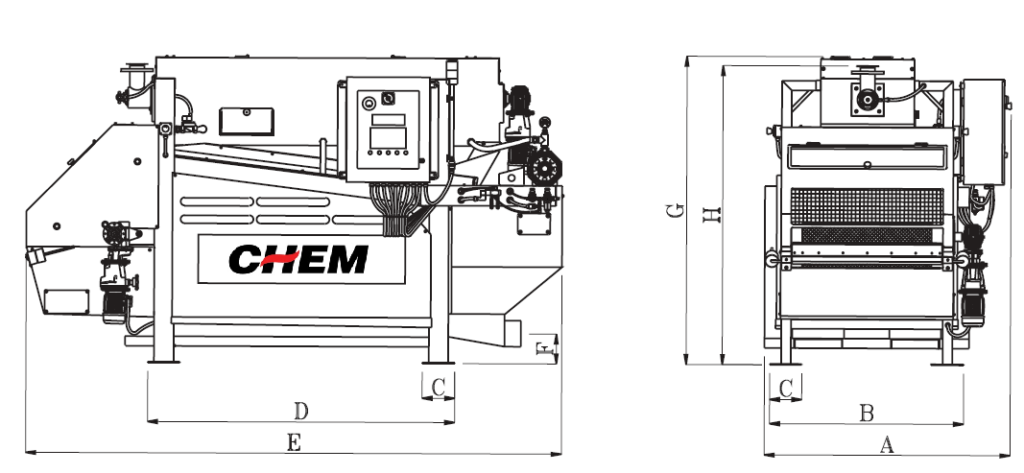

Mono Belt Filters

The term filter itself indicates the matter of the fact that a higher particle size needs to be segregated or separated from a lower particulate size, from a mix forming a solid-solid mix or a solvent and solute mix. This is generally done by incorporating a fine go through membrane, which allows passing of particles with lower particle size. This is one of the most common and effectively practiced means of separation since long time.

Belt Filters are a device which is made up of a membrane generally used in separation of solids and liquids.

The system is so designed that the membrane forms a long and continuous belt structure which is passed over various drums or rollers, and these drums are kept under rotation, which initially allows the liquid to pass by gravity and since the rollers are rotating it builds in a squeezing process allowing the remaining liquid to pass through the membrane belt and keeping the solids on the other side.

The Belt Filters are generally used in the Sludge dewatering, Solid recovery from slurries or in Juice or pulp extraction in Fruit and vegetable industries. Since it is a simple mechanism, and works on low pressure fundamentals it is widely used in the applications where the quantity of fluid is in small scale and the primary intent of the process is to just separate the maximum solid-liquid.It is a continuous process. Generally the solids that are received at the end of the process carry 12% – 15 % moisture of the liquid.

The belt press may be fitted with a highly efficient belt pre-dewatering unit of the same high standard design as the belt press. The belt speed may be adjusted by means of a frequency controlled gear motor. All monitoring functions may be integrated in the control cabinet of the belt press. The pre-dewatering unit is typically fitted where the dry matter content of the sludge is below 2%. If you would like further information on the pre-dewatering unit, for instance capacities, do not hesitate to contact us.

With Proficiency in providing various models for different applications, the Mono Belt Filters can be well customized for different aspects of solids, moisture content, various materials of constructions. And to boast on one of the best service networks across the country.

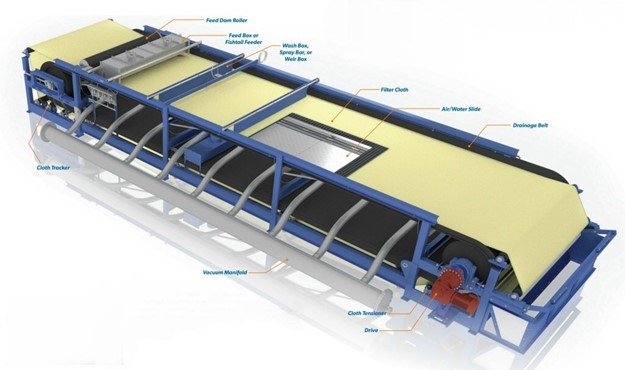

Vacuum Belt Filters

Chem Process make Horizontal Vacuum Belt Filters provide a continuous vacuum on a horizontal plane. Slurries are fed onto a filter cloth supported by a traveling drainage belt. Horizontal belt filters are especially adaptable to applications where low cake moisture is desirable.

Backed by extensive practical experience gained from a wide range of applications Chem Process offers a complete engineering and contracting service to the liquid/solids separation industry. Chem Process make horizontal belt vacuum filters have been developed and improved in mechanical design by working closely with engineers and operators at many key installations.

Chem Process offers a wide range of units from the smallest 10 ft2 up to 2000 ft2 in effective filtration area. All of these units are capable of running at speeds up to 200 ft/minute at vacuum levels up to 25 inches of mercury at sea level.

Making use of the most modern materials of construction, Chem Process make Belt Filters latest designs outperform traditional rotary drum, disc tilting pan and table filters in all situations, both in throughput and final cake moisture.

Features

- Single Source Supplier for Full FGD Process Train

- Broad Process Experience

- Robust Construction

Benefits

- High Efficiency Dewatering

- Low Cake Moisture

Applications

- Coal

- Phosphoric acid

- Chemicals

- Copper leach

- Gold

- Industrial minerals