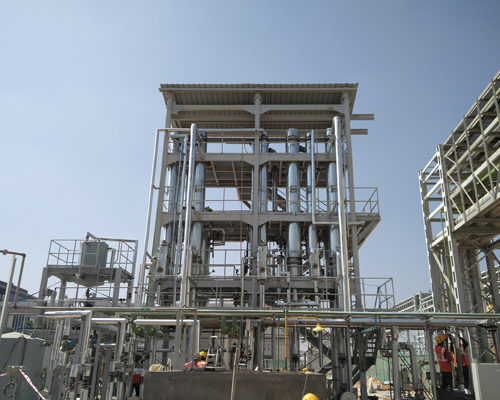

Zero Liquid Discharge Systems

Large quantities of industrial waste waters/effluents with strong contaminations of different compositions are generated in the production and processes of almost all industrial sectors. These waste waters have to be treated before they can be discharged into the specified permissible system.

Hence an efficient and environmentally friendly waste water treatment is required. Chem Process partners with you to provide the best solutions for treatment of industrial waste waters.

As one of the leading designers and manufacturers of thermal and mechanical process equipment with core competence in evaporation, crystallization, vacuum and heat transfer, Chem Process offers custom made plants with additional upstream or downstream process steps. Suitable combinations of processes in our plants achieve optimum results for the recovery of water and valuable products.

Technologies

During the design of evaporation plants, numerous factors have to be taken into consideration viz. waste water specific product values, power and utility costs and site condition. The type of construction and arrangement, other process engineering and operational data are based on these parameters.

Research & Development

Chem Process has an in-house research and development centre with the required laboratory equipment, where waste waters are tested and treated for their behavior and based on the results, appropriate plant components, pre and after treatment are selected and designed. Mobile pilot plants are also available, which if required are sent to our customer’s location for carrying out tests.

Energy savings are possible by :

- Heating with Waste Heat

- Multi-Effect Evaporation

- Thermal Vapor Compression

- Mechanical Vapor Compression

If the characteristics of the waste waters cannot be clearly defined and if its constituents, dry matter contents, pH or particle size change frequently, and if they have to be concentrated substantially, then thermal separation is the best solution.

Energy consumption determines the operating costs of evaporation plants. With our ingenious thermo-technical combinations, the plant energy requirement is minimal.

Salient Features

Plants designed and engineered by Chem Process are recognized for their high quality, efficient performance and economic operation. All process and functional requirements are taken into consideration and hence operations of a Chem Process designed plant are reliable and operator friendly.

- Operation reliability is high

- Long plant life

- Good performance even at partial capacities

- Custom designed plant configurations

- Bespoke component designs

- Combination of several process steps, which include pre and after treatment

- Maximum concentration of waste waters

- Minimal use of chemicals

- Total separation of solids

- Condensate/distillate water has salts > 100 ppm

- Minimal residual bleed and solid matter quantities, hence low disposal costs

- Good condensate quality, hence can be reused as process water in most cases

Our scope of services include consultancy, design, engineering calculations, manufacturing, quality control, delivery, supervision of erection, commissioning and after-sales services. Chem Process has:

- Delivered to more than 800 plants

- Extensive knowledge on products to be handled

- In-house research and development centre with laboratory and pilot plants

- Mobile pilot plants available for on-site trials

- A wide sales network of representatives and partner offices

- ISO 9001 2008, Asme ‘U’ and National Board ‘R’ Stamp certified fabrication shop