Agitated Thin Film Dryers-Chem Process System

Chem Process Systems manufactures and supplies a comprehensive range of equipment, including Agitated Thin Film Dryers, Ejectors, Vacuum Systems, Distillation Units, Gas Extraction and Generation Systems, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, and Ethylene Glycol Vacuum Systems.

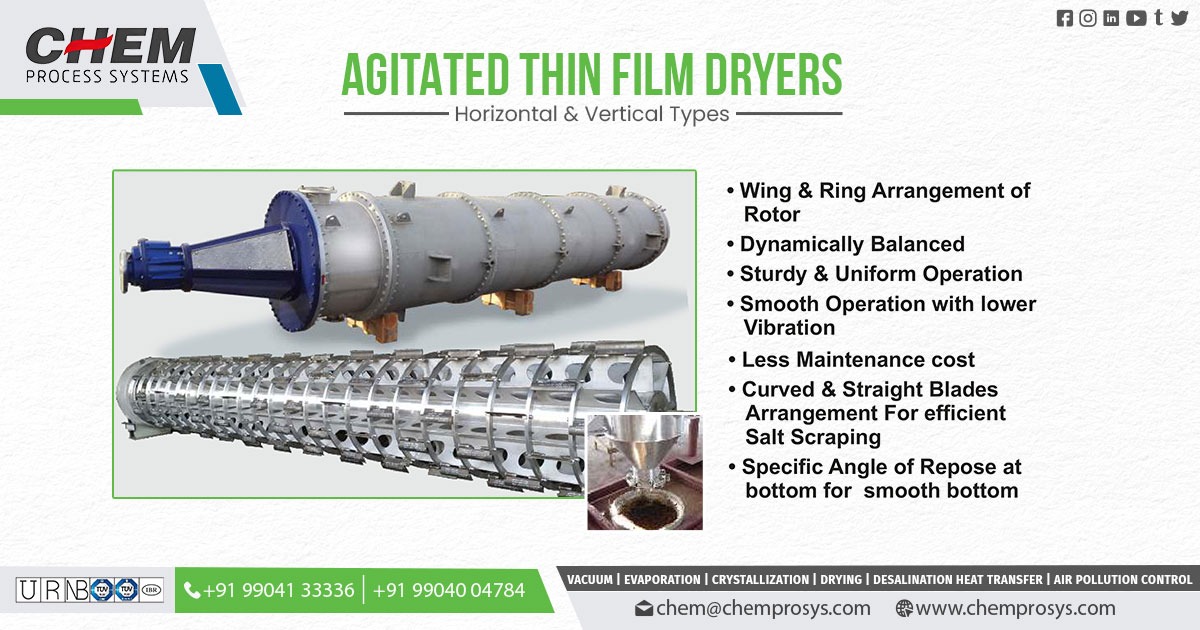

The Agitated Thin Film Dryer (ATFD) is pivotal for vacuum drying heat-sensitive products and ensuring full solvent recovery.

This high-throughput system efficiently operates under vacuum conditions, employing indirect heating and drying in inert environments. This approach is particularly effective for heat and oxygen-sensitive products.

Our vertical ATFD design caters to a wide spectrum of process fluids, including liquids, slurries, and pastes. By enabling a continuous single-pass operation, these process fluids are transformed into free-flowing solids.

Our dryers are widely used across various industries to convert liquids, slurries, and pastes into free-flowing solids through continuous single-pass operation.

The self-cleaning heating surfaces of our dryers minimize maintenance requirements for moving parts over the long term.

Advantages:

Excellent heat conductivity (k-value), even with highly viscous and contaminated products

The synergy of low operating capacity and brief dwell time results in minimal thermal stress, elevating overall performance significantly.

High evaporation rates attributed to highly turbulent film and significant temperature differences

Gentle evaporation resulting from short residence times, rapid conveyance in the heated zone, and constant product film renewal

Furthermore, applying vacuum operation leads to lowered boiling points, yielding a substantial overall process efficiency improvement.

Thin film thickness without hydrostatic height

High turndown ratio and flexibility for varying requirements

Low operating pressure, reaching as low as 1 micron to lower boiling temperature

These systems find application in Zero Liquid Discharge systems for drying concentrated effluents, preventing thermal degradation by reducing impurities, and enhancing the removal of highly volatile components from viscous products.

Furthermore, they aid in producing continuous dry powder, concentrating Vegetable Extracts, Animal Products, sugars, Bio-Acids, Bio-alcohols, and more.

Chem Process Systems proudly serves as a Manufacturer and Supplier of Agitated Thin Film Dryers.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.