Chem Process Systems Pvt. Ltd. Offer Wastewater and Effluent Treatment Plant for Agrochemical Industries across India.

Agrochemical industries play a critical role in enhancing agricultural productivity through the manufacturing of fertilizers, pesticides, herbicides, and insecticides.

However, these processes often generate large volumes of contaminated wastewater and chemical effluents.

To minimize environmental damage and ensure compliance with environmental regulations, Wastewater and Effluent Treatment Plants (ETPs) are essential.

We specialize in designing and delivering advanced, customized Effluent Treatment Plants for agrochemical industries.

Our systems are engineered to treat complex wastewater streams, ensuring safe discharge or reuse while adhering to local and international environmental standards.

Features of Wastewater and Effluent Treatment Plant

• Multi-Stage Treatment: Includes physical, chemical, and biological treatment stages.

• Advanced Technologies: Integration of reverse osmosis (RO), ultrafiltration (UF), activated sludge process, and MBR (Membrane Bio-Reactor) systems.

• Automation & Monitoring: SCADA-based real-time monitoring and control systems for efficient plant operation.

• Energy-Efficient Design: Reduced operational costs with optimized power and chemical consumption.

• Corrosion-Resistant Materials: High-quality construction ensures durability and minimal maintenance.

• Compliance Assurance: Meets CPCB, EPA, and international discharge norms.

Work of Wastewater and Effluent Treatment Plant in Agrochemical Industries

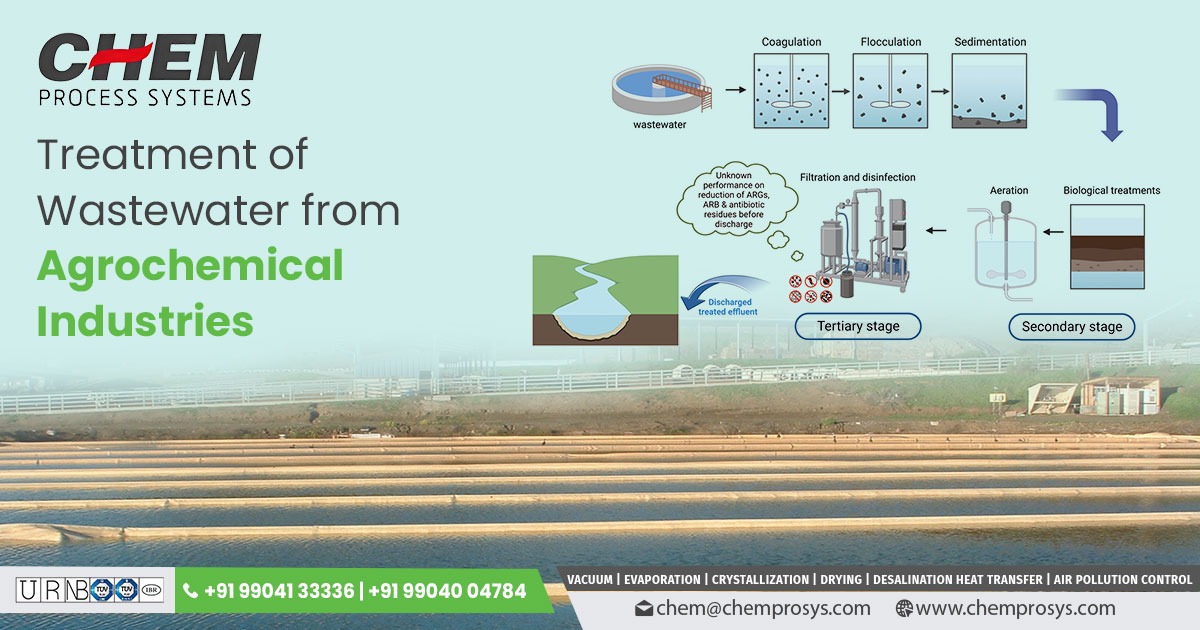

The treatment process in agrochemical industries typically involves several key stages:

- Pre-Treatment: Screening and neutralization of pH levels to prepare effluents for further processing.

- Primary Treatment: Removal of suspended solids and oil through sedimentation and flotation methods.

- Chemical Treatment: Coagulation, flocculation, and oxidation to eliminate toxic chemicals and heavy metals.

- Biological Treatment: Use of microbial cultures to break down biodegradable organic matter.

- Advanced Treatment: Technologies such as RO and activated carbon filters for removal of micro-pollutants.

- Sludge Handling: Dewatering and safe disposal of residual sludge.

- Disinfection & Reuse: UV or chlorine disinfection, with options for water recycling in non-potable processes.

Uses of Wastewater and Effluent Treatment Plant in Agrochemical Industries

• Treatment of pesticide and herbicide-laden wastewater

• Neutralization of acidic or alkaline effluents

• Removal of heavy metals and toxic substances

• Water recycling for cooling towers and process applications

• Compliance with zero liquid discharge (ZLD) mandates

• Sludge management and disposal

FAQs

Q1. Why do agrochemical industries need effluent treatment plants?

Agrochemical industries generate wastewater with high chemical toxicity, which can severely damage the environment if untreated.

Q2. What types of pollutants are removed in Chem Process’s ETPs?

Our ETPs remove organic and inorganic chemicals, pesticides, herbicides, heavy metals, TDS, COD, BOD, and suspended solids.

Q3. Can treated water be reused in the plant?

Yes. Our systems support water reuse in non-potable processes like cleaning, cooling, and irrigation, helping reduce water consumption.

Q4. How does Chem Process ensure compliance with pollution control norms?

We incorporate advanced monitoring systems and design treatment processes that meet CPCB and international environmental standards.

Q5. Do you offer Zero Liquid Discharge (ZLD) solutions?

Chem Process Systems Pvt. Ltd. provides ZLD-compliant systems tailored to the needs of agrochemical manufacturers.

Contact us today to discuss your requirements or request a site visit.

View Product: Click here