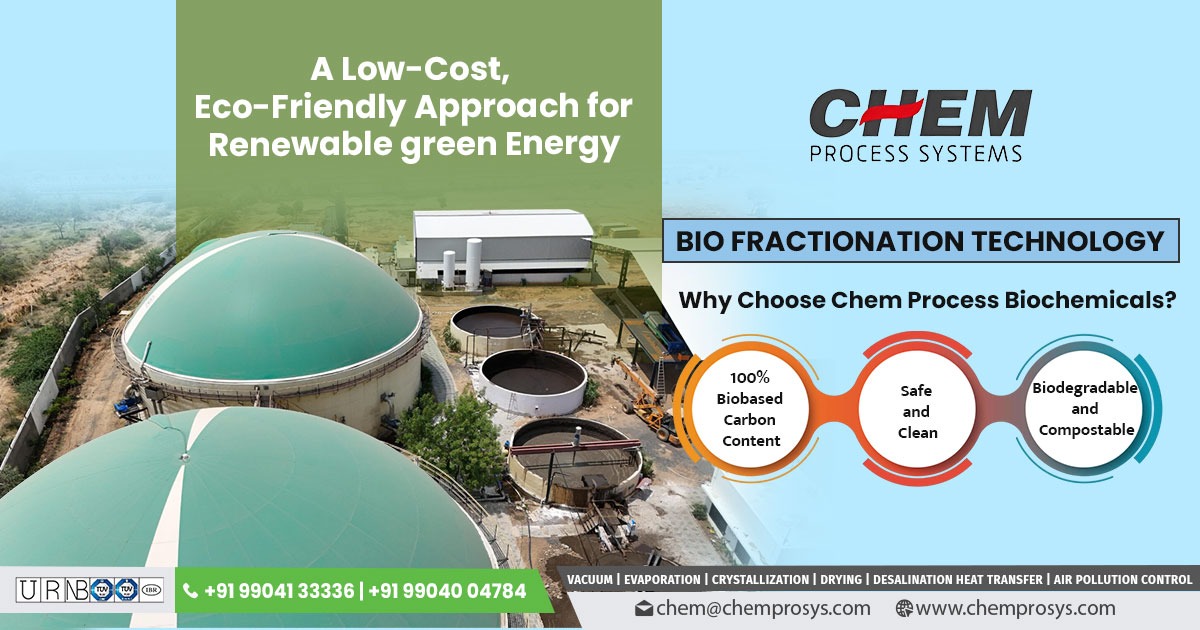

Chem Process Systems Pvt. Ltd. Bio Fractionation Technology across India.

Our registered office is located in Sanand, Ahmedabad, Gujarat, India.

Why Choose Chem Process Biochemicals?

- 100% Biobased Carbon Content

- Verified by ASTM D6866 testing, sourced from renewable biomass.

- Safe and Clean

- Exceptionally low Polycyclic Aromatic Hydrocarbons (PAHs), compliant with EU and Indian regulations.

- Biodegradable & Compostable

- Certified under IS 17088 for biodegradability in industrial, home, soil, and marine environments.

Our Process: From Agricultural Waste to Valuable Products

- Sourcing Sustainable Biomass

- Responsibly sourced thinning and industrial hardwood from regional forests.

- Wood is debarked, chipped, and pre-treated to separate hemicellulose.

- Hemicellulose to Industrial Sugars

- Conversion of hemicellulose into industrial sugars.

- Sugars are further processed into fuels, food ingredients, and polymers.

- Cellulose to Renewable Glycols

- Enzymatic conversion of cellulose into renewable glycols like BioMEG and BioMPG.

- These are 1:1 drop-in replacements used in textiles, coolants, and packaging.

- Lignin to Advanced Biochemicals

- Lignin transformed into Chem BioMotion™ RFF.

- Sustainable alternative to carbon black and precipitated silica for rubber and plastic industries.

Our Mission

- Turning agricultural waste into sustainable biochemicals, fuels, polymers, and materials.

- Maximizing the use of every part of biomass for eco-friendly production.

- Promoting renewable energy through biogas production, reducing greenhouse gas emissions.

Composition of Agricultural Waste

- Cellulose (50%): Primary structural polymer providing strength to biomass.

- Lignin (25%): Adds rigidity and resistance to water and degradation.

- Hemicellulose (25%): Binds cellulose and lignin, aids in water retention within cell walls.

Bio Fractionation Plant – Innovation & Sustainability

- Combines advanced chemistry with sustainable wood processing.

- Extracts and refines cellulose, lignin, and hemicellulose into high-value biochemicals.

Revolutionizing Rubber and Plastics Industry with Chem Process RFF

- Carbon Footprint Reduction: Replaces CO₂-intensive carbon black and precipitated silica, cutting environmental impact by 50% or more.

- Lightweight Advantage: 25% lighter than carbon black and 35% lighter than precipitated silica, enabling up to 20% weight reduction in final products.

- High Performance: Enhances rubber’s resistance to non-polar media and supports advanced processing techniques.

Applications Across Industries

- Thermoplastics

- Provides distinctive black color, thermal stability, and recyclability.

- Used in packaging, automotive components, and more.

- Biodegradable Products

- Suitable for compostable products, reinforcing circular economy goals.

Chem Process Systems Pvt. Ltd. Bio Fractionation Technology across India.

For more information, please feel free to contact us.

Website: http://www.chemprosys.com

Email Id: chem@chemprosys.com

Phone No: +91 99041 33337

View Product: Click here