Chem Process Systems Pvt. Ltd. is a leading manufacturer and supplier of high-quality De-Superheaters designed for efficient steam temperature control in industrial

applications.

Our registered office is located in Sanand, Ahmedabad, Gujarat, India.

Our De-Superheaters bring superheated steam down to its saturated state or reduce its temperature to a level suitable for heating processes, ensuring maximum

efficiency and reliable operation.

Industries widely use De-Superheaters where steam recovery and precise heating control are essential, providing a cost-effective and energy-efficient solution.

Work of a De-Superheater

A De-Superheater reduces the temperature of superheated steam in a controlled manner using water or other compatible liquids/gases. The process involves:

• Injection: Water (or compatible fluid) is injected into the superheated steam path.

• Atomization: The injected liquid is atomized to ensure uniform mixing with the steam.

• Controlled Cooling: Steam temperature is reduced gradually to the desired saturated level suitable for heating applications.

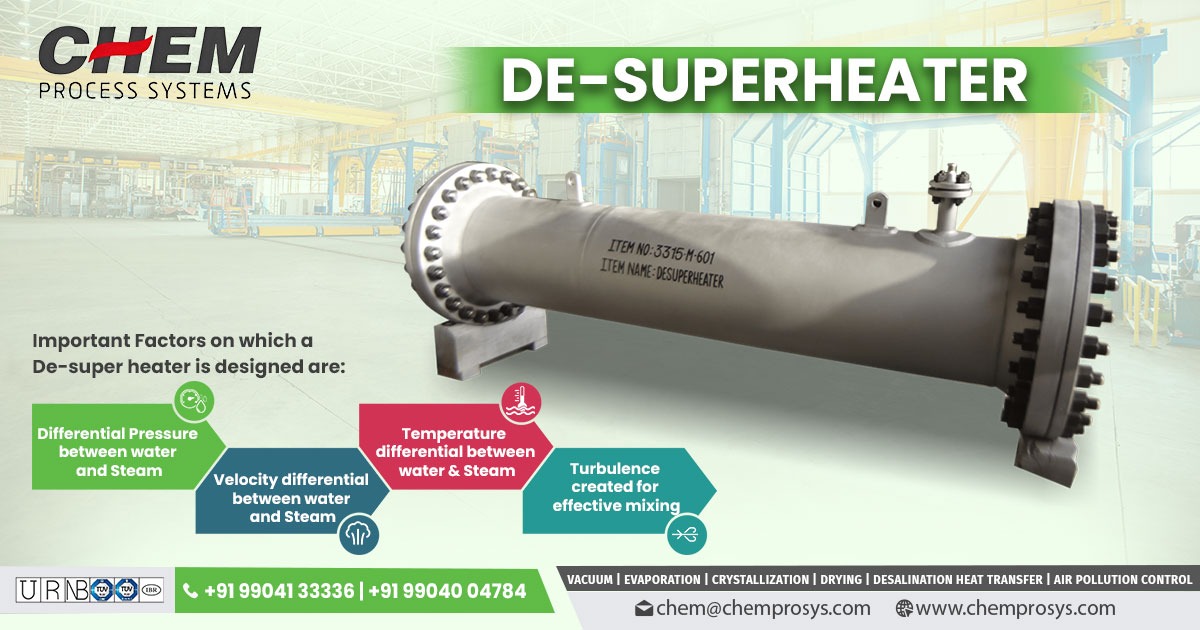

Key Design Factors:

- Differential Pressure: Between injected water and incoming steam.

- Velocity Differential: Between water droplets and steam flow.

- Temperature Differential: Between water and steam for efficient cooling.

- Turbulence: Created to promote proper mixing and uniform temperature distribution.

Why Choose Our De-Superheaters?

Chem Process Systems Pvt. Ltd. provides De-Superheaters designed for performance, reliability, and efficiency.

Advantages of our De-Superheaters:

• Ensures uniform heat distribution, avoiding hot and cold patches on heating surfaces.

• Optimizes steam usage, converting injected water into steam without loss of energy.

• Improves plant efficiency by speeding up the heating process.

• Reduces waste of valuable steam in industrial operations.

• Easy to install and operate, with minimal maintenance requirements.

Uses of De-Superheaters

Our De-Superheaters are ideal for various industrial steam applications, including:

• Power generation plants for steam recovery and reuse.

• Chemical and process industries requiring controlled heating.

• Boilers and heat exchangers where steam temperature control is critical.

• Textile, paper, food, and pharmaceutical industries for precise heating processes.

Frequently Asked Questions (FAQs)

Q1. What is the main purpose of a De-Superheater?

A: A De-Superheater reduces superheated steam to saturated steam, ensuring uniform temperature and efficient heat transfer for industrial processes.

Q2. How does a De-Superheater work?

A: It injects water or compatible liquids into superheated steam in a controlled manner. The water atomizes and mixes with the steam, reducing its temperature to the desired level.

Q3. What fluids can be used in a De-Superheater?

A: Typically water is used, but other compatible liquids or gases can also be utilized based on process requirements.

Q4. What are the key factors in designing a De-Superheater?

A: Differential pressure, velocity difference, temperature difference between fluids, and turbulence for effective mixing.

Q5. What are the benefits of using a De-Superheater?

A: Uniform heat distribution, increased plant efficiency, reduced steam wastage, and improved heating performance.

Chem Process Systems Pvt. Ltd. is a De-Superheater Manufacturer and Supplier across India.

For more information or inquiries, please get in touch with us:

Website: http://www.chemprosys.com

Email: chem@chemprosys.com

Phone: +91 99041 33337

View Product: Click here